냉동 난방 온도 제어 시스템 장비의 크기 및 설치 높이 정보

Whether it is biopharmaceutical, traditional Chinese medicine or chemical pharmacy, pharmaceutical companies are all related to chemistry, because the extraction and synthesis of pharmaceutical ingredients are all in the form of chemical products. Therefore, as long as there are many links in the process, there are explosive substances such as acetone, alcohol, etc. There are also raw materials in the warehouse, dust in the workshop, and pressure in the reactor.

Temperature control equipment is essential for these enterprises, and the price is relatively expensive, so such customers are customized explosion-proof cooling and heating units. The explosion-proof standard of our LNEYA is in accordance with national regulations, the explosion-proof mark is Expxdmb Ⅱ CT4, and the explosion-proof qualification is just GYB091118. The positive pressure explosion-proof cabinet is composed of a positive pressure chamber and a control chamber. The positive pressure chamber is used to install various non-explosion-proof instruments or electrical appliances. The control chamber is composed of an explosion-proof control box and a pressure control system. The isolation explosion-proof mark is EXd ⅡBT4, and the electrical cabinet adopts explosion-proof type. Therefore, during the initial communication, our technicians will confirm with the user whether there are explosion-proof requirements.

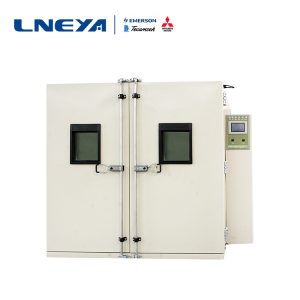

Here we mainly introduce the hardware data of our LNEYA refrigeration heating temperature control system. Because we accept customer’s customization, we will rationally design the appearance of each plate according to the customer’s use site. Such as the size of the equipment, the position and size of the inlet and outlet, and the installation height. Industrial temperature control equipment will not be miniature, and its length, width and height are definitely higher than that of an adult. Secondly, the pipeline of cooling water circulating water needs to be informed of the working conditions on site, so that the size and position of the inlet and outlet and the data interface area can be determined before production. Normally, the medium inlet and outlet of our equipment is located on the left side of the rear of the equipment, the pressure gauge is located under the left side of the rear, and the data interface is located under the front color control screen. You can take a closer look at the actual appearance of the device.

관련 권장 사항

-

Analysis of Static Strength of Battery Box in Power Battery Test and Analysis System

1382The battery box of new energy vehicles is one of the core components of electric vehicles. Designing high-strength, high-rigidity, high-security, high-lightweight battery boxes is of great significance to the development of electric vehicles. Over...

세부 정보 보기 -

냉난방 온도 제어 시스템을 선택하는 방법은 무엇인가요?

1151냉동 난방 온도 제어 시스템의 가격은 주요 요인이 아닙니다. 주요 목적은 온도 제어 기능을 통해 온도 제어 기술을 구현하는 것입니다. 그러나 온도 제어 시스템이 아닙니다 ...

세부 정보 보기 -

Step-by-step test box brand advantage description

1294The walk-in test box is developed and produced by LNEYA. It is specialized in pharmaceutical production technology and provides customers with various models of brands. Next, we will introduce the next step-in test box. Welcome to refer to and lea...

세부 정보 보기 -

자동차 냉각수 주기 관리의 중요성

1135Even if the overall running quality of the car cooling water circulation machine is high, if there is no maintenance and maintenance in the specified time, the car cooling water circulation machine may have different degrees of failure. Especially...

세부 정보 보기

LNEYA 산업용 냉각기 제조업체 공급 업체

LNEYA 산업용 냉각기 제조업체 공급 업체