Description of power consumption in LNEYA large refrigeration unit

In the process of operation, the cooling capacity and working conditions will affect the power consumption of the entire large refrigeration unit, but in order to avoid unnecessary power consumption, we need to understand the other power consumption in the refrigeration unit.

When the scale of the wall of the condenser of the large refrigeration unit reaches 1.5 mm, the condensation temperature rises by 2.8 °C than that before the fouling, and the power consumption increases by 9.7. The surface of the evaporator is covered with a layer of frost, which reduces the heat transfer coefficient. Especially when the outer surface of the finned tube is frosted, it not only increases the heat transfer resistance, but also makes the air flow between the fins difficult, reducing the appearance of the heat. Thermal coefficient and heat dissipation area. When the ambient temperature is lower than 0 °C, the temperature difference between the two sides of the evaporator tube set is 10 °C. After the evaporator is operated for one month, the heat transfer coefficient is about 70 before frosting.

The gas sucked by the compressor of the large refrigeration unit allows a certain degree of superheat, but the superheat is too large, the specific volume of the suction gas increases, the cooling capacity decreases, the relative power consumption increases, the compressor comes to frost, and the small suction valve is quickly closed. , drastically reduce the amount of cold produced, and relatively increase the power consumption.

As the evaporation temperature of large refrigeration units decreases, the compression ratio of the compressor increases, and the energy consumption per unit of production increases. When the evaporation temperature is lowered by 1 ° C, it consumes 3% to 4% more. Therefore, the evaporation temperature difference is reduced as much as possible, and the evaporation temperature is increased, which not only saves power consumption, but also improves the relative humidity of the cold room.

As the condensing temperature of the large refrigeration unit increases, the compression ratio of the compressor increases, and the energy consumption per unit of cooling capacity increases. When the heat exchange surface of the condenser and evaporator of a large refrigeration unit is covered with an oil layer, the condensation temperature rises and the evaporation temperature decreases, resulting in a decrease in cooling capacity and an increase in power consumption. When air collects in the condenser, it causes an increase in the condensing pressure and an increase in the power consumption of the compressor.

When the same large-scale refrigeration unit has the same structure and rotating speed, the cooling capacity and power consumption are different when the operating conditions are different. Therefore, the operator is operating after understanding and avoiding the increase of the operating cost of the enterprise.

관련 권장 사항

-

다양한 주변 온도에서의 배터리 충전 테스트 조건

1313현재 배터리는 의심할 여지 없이 전기 자동차에서 가장 핵심적이고 중요한 부품입니다. 따라서 OEM과 배터리 공장 모두 배터리에 대한 포괄적인 테스트를 수행해야 합니다. 자동차 리튬 이온 배터리의 특성 ...

세부 정보 보기 -

증착 코팅기 온도 제어 시스템-냉각수 시스템

1190The main purpose of the vapor deposition coating machine is to carry out scientific experiments and research on film formation process. It is composed of quartz tube reaction chamber, heat shield furnace cabinet, electrical control system, vacuum ...

세부 정보 보기 -

유리 반응기는 어떻게 선택하나요? 온도 제어 시스템을 맞추는 방법은 무엇인가요?

1006유리 주전자 반응기는 많은 실험실 장비에 필요하며 일반적으로 온도 제어 시스템과 함께 사용됩니다. 화학 및 제약 분야에서 수입 유리 반응기는 기본적으로 필수품이며 냉장 가열 ...

세부 정보 보기 -

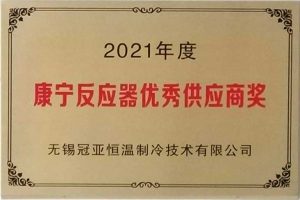

"2021년 원자로 온도 제어 장비 우수 공급업체" 수상

3140미국 포춘지 선정 500대 기업인 코닝이 선정한 '2021 우수 리액터 기술 공급업체'로 선정되었습니다. 2015 년부터 LNEYA는 7 년 연속이 상을 수상했습니다. 따라서 원자로 제조 산업에서 우리는 ...

세부 정보 보기

LNEYA 산업용 냉각기 제조업체 공급 업체

LNEYA 산업용 냉각기 제조업체 공급 업체