진공 챔버 냉장 난방 온도 조절기 제어 장치에서 에너지를 절약하는 방법

에너지 절약 및 배기가스 저감 운영 환경에서 LNEYA 진공 챔버 냉각 및 가열 온도 조절기 제어 장치를 작동하는 방법은 매우 중요합니다. 소비를 줄이기위한 몇 가지 팁을 살펴보고 사용 방법을 살펴 보겠습니다.

The very important first step in the selection of the vacuum chamber cooling and heating thermostat control unit is that the cooling capacity is too small, which affects the production, and often loses more than the loss; however, the excessive cooling capacity will inevitably increase the cost of the enterprise and cause unnecessary waste. It is recommended that the manufacturer introduce the detailed process in the process of purchasing, and let the professional personnel calculate the appropriate model, the object to be cooled and the time required to reduce the required temperature.

In this process, we must pay attention to some manufacturers to do some small articles on the cooling capacity, often exaggerating the energy efficiency ratio, in fact, these things can pay attention to the greasy ones, there are related data showing the cooling capacity power theoretically. Data, in the actual production process, the cooling capacity will be lower than the theoretical value, according to the actual situation of the environment, the cooling capacity will fluctuate.

The vacuum chamber refrigeration heating constant temperature control unit increases the evaporation temperature under the premise of ensuring the production demand and meeting the safety of the equipment or the product, and appropriately reduces the condensation temperature and increases the flow rate of the cooling tower to ensure the cooling water effect;

Improve regular daily maintenance work, regularly clean the pipeline, reduce pipe resistance and prevent pipe fouling, increase flow, ensure that the evaporator and condenser fully replenish water, enhance heat transfer efficiency, and unclean water source during long-term use. Will produce calcium carbonate and magnesium carbonate deposition pipelines, affecting heat transfer efficiency, increase the power required for the operation of the equipment, so that the electricity costs increase significantly, invisibly increase the cost of the enterprise.

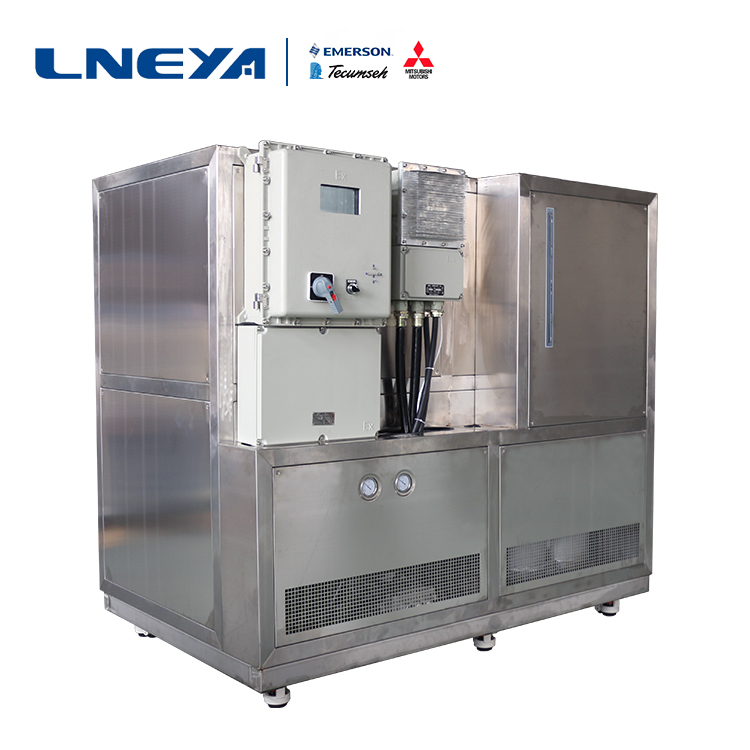

The LNEYA vacuum chamber refrigeration heating constant temperature control unit adopts a fully enclosed pipeline. In the process of operation, the energy consumption ratio can be reduced to a certain extent, so that the vacuum chamber refrigeration heating constant temperature control unit operates efficiently.

관련 권장 사항

-

Why does the heat transfer oil control system device heat transfer oil coke exist?

1010In the heat transfer oil control system device, the heat transfer oil is used for the cooling and heating temperature control. If it is not the same as the LNEYA, the use of the fully closed circuit can affect the formation of certain coking, resu...

세부 정보 보기 -

Aerospace equipment parts cryogenic test freezer refrigeration troubleshooting instructions

1310Cooling water inlet temperature is too low Ultra-low temperature freezer for ultra-low temperature testing of aerospace equipment components As the temperature of the cooling water decreases, the compressor discharge pressure, exhaust temperature,...

세부 정보 보기 -

What are the applications of external circulation oil chillers?

1151External circulation oil chillers are mainly used in the industrial field, especially suitable for situations that require cooling oil to maintain normal equipment operation and extend equipment service life. The following are some typical...

세부 정보 보기 -

극저온 저장 탱크(방폭형) 화학 극저온 저장소

1205제품 개요 : 마이크로 컴퓨터 제어, 다중 보안 보호 및보다 안정적인 작동; 단일 압축기 자동 캐스케이드 과냉각 냉동 기술; 압축기는 Secop 및 프랑스 Taikang 브랜드를 사용합니다접촉기 및 회로 브래킷 ...

세부 정보 보기

LNEYA 산업용 냉각기 제조업체 공급 업체

LNEYA 산업용 냉각기 제조업체 공급 업체