Energy Conservation is Crucial for Developing Ultra Low Temperature Recirculating Chillers

With the continuous development of chemical, refrigeration and pharmaceutical industries, environmental pollution is put on the agenda earlier. As an editor of which is the industrial chiller, I can say that except for corresponding to the environmental protection theme, we apply environmental friendly ultra low temperature recirculating chillers for the equipment, increasing the efficiency constantly. So what should be done specifically?

Industrial chiller units lower the condensing temperature in the conditions of evaporating temperature, and increase the vaporization point and reduce the condensation temperature as much as possible when meeting the requirement of safety and manufacture, ensuring the cooling water efficiency and enlarging the change of cooling tower.

I should tell you that for the sake of ensuring the industrial chiller to operate safely, the power dissipation of a number of cold energies is smaller. It should consider the operating situations of the water pump and cooling tower comprehensively while taking this method into effect.

To prevent and reduce the pipe scaling of industrial chiller is for enhancing the heat transfer efficiency of the condenser and evaporator. If the make-up water is treated badly, calcium carbonate and magnesium carbonate produced by calcium bicarbonate and magnesium bicarbonate through heating will precipitate on the pipes, decreasing the heat-conducting property to have an impact on the heat exchange efficiency of condenser and evaporator and increase the electric charge by a large margin for chiller’s operation. Apart from using water treatment technology, I will tell you that you can apply the equipment for cleaning the pipes regularly, which can save the electric quantity and at the same time level up cooling-water machine’s effect.

When centrifugal refrigeration machine’s compressor is adjusted by the frequency converter of industrial chiller units on account of revolving speed, the pressure will be raised as low-tension refrigerant goes through hydroextractor. The faster the rotational speed is, the higher the pressure is. In actual operation, the equipment works without a full load. The centrifugal machine with fixed revolving speed operating in small load will waste the energy. While frequency converter of the refrigerator will regulate the speed of compressor automatically according to the change of load, having greater potential for energy saving.

When mastering the four points mentioned above, I am sure the working efficiency will be improved better. It is necessary to follow these steps so as to protect the environment!

관련 권장 사항

-

자동차 냉각수 주기 관리의 중요성

1135Even if the overall running quality of the car cooling water circulation machine is high, if there is no maintenance and maintenance in the specified time, the car cooling water circulation machine may have different degrees of failure. Especially...

세부 정보 보기 -

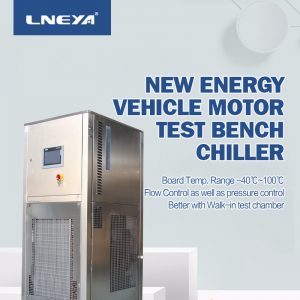

Hybrid car battery test equipment cooling capacity description

1062Due to insufficient insulation thickness of the hybrid vehicle battery test equipment and pipeline or damage to the insulation layer, the loss of cooling capacity is increased, which affects the cooling effect. In the operation of the hybrid vehic...

세부 정보 보기 -

LNEYA: Focus on temperature control TCU to build international advanced Chinese instruments

1093Wide temperature range: LNEYA's Chinese and production-grade multi-reactor refrigeration heating temperature control system (temperature control unit TCU) temperature range from -25 ° C to 200 ° C, of course, you can also customize other temperatu...

세부 정보 보기 -

냉동 난방 기계 파이프 설명

1124냉동 및 난방 통합 기계가 작동 중일 때 사용자는 완전히 밀폐 된 파이프 라인이 장비의 전체 성능에 영향을 미치는지 여부를 알 수 있습니다. LNEYA 냉동 및 난방 통합 기계는 완전 밀폐형 기계를 채택합니다.

세부 정보 보기

LNEYA 산업용 냉각기 제조업체 공급 업체

LNEYA 산업용 냉각기 제조업체 공급 업체