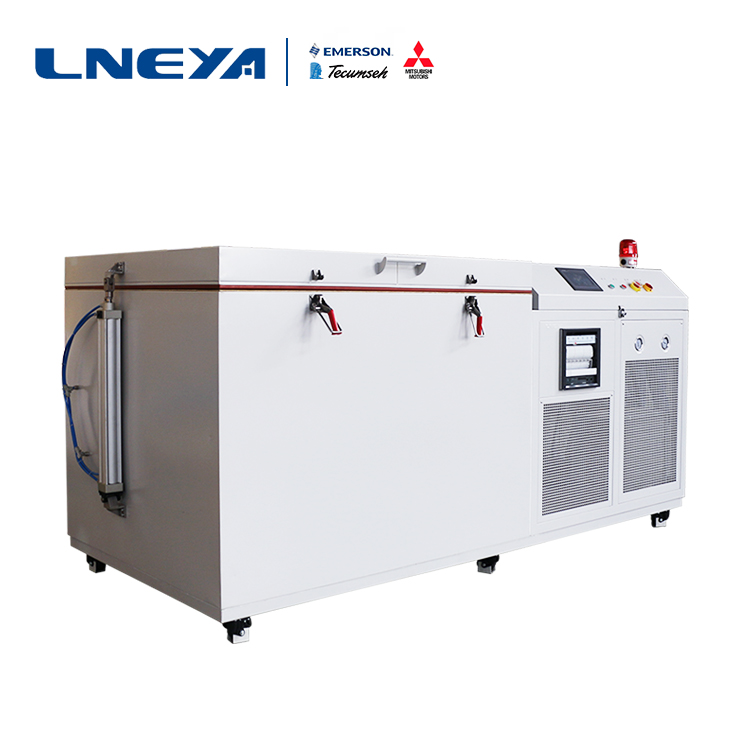

How to prevent the freezing pressure of the bearing quick freezing box from being too low?

In the refrigeration system of the bearing blast chiller, if the condenser installation is not in the enclosed space, the system’s exhaust pressure (condensation pressure) tends to be lower in winter (or low temperature), which is often more common in the north. For bearing blasters, this is also the case for other equipment.

The low condensing pressure of the bearing quick freezing box will make the expansion valve unable to obtain sufficient pressure drop at both ends, and it is difficult to supply the appropriate refrigerant to the evaporator. On the one hand, the cooling capacity of the refrigeration system will not meet the requirements, and the system will also be made. Frequent low-voltage alarms and other faults.

To this end, we can deal with the method of exhaust pressure controller. When the intermittent operation of the fan is simple and easy to use, and the technology is mature, the controller used is a pressure controller. This pressure controller can control the intermittent start and stop of the fan. When the pressure is too low, turn off the fan. When the pressure is too high, turn on the fan. Generally, on a small-capacity unit, use two or more fans, one of which is normally open, and the other fans are pressure controlled. The controller controls the start or stop of the fan by the level of the condensing pressure.

It is also possible to use a pneumatic control device to utilize a high-pressure refrigerant-driven piston-type damper. This control device can operate as a stable exhaust pressure as the fan speed controller; the main reason is that the inlet pressure of the expansion valve does not resemble a fan. Intermittent operation produces large fluctuations, and the louver device can be installed either at the air inlet or at the air outlet.

In addition, the condenser overflow device can also be used to increase the condensing pressure of the system by using excess refrigerant, and the condenser overflow device is used for warming or low temperature environment, and the large flow refrigerant is taken from the liquid storage device. It is sent to the condenser, and the excess refrigerant is used to increase the condensing pressure of the system, thereby avoiding the failure of the condensing pressure being too low at low temperatures.

LNEYA’s methods to prevent the bearing chiller from condensing too low pressure are still relatively high, and users can try it according to their own needs.

관련 권장 사항

-

What are the main hazards of the reaction kettle in the reactor intelligent temperature control syst

1185The intelligent temperature control system of the reactor is used in various chemical fines. With the constant attention of the industry safety issues, some risk factors of the intelligent temperature control system of the reactor should be avoide...

세부 정보 보기 -

Wuxi Guanya Low Temperature Test Chamber With 12 Years Brand ranked the top ten in China!

728Throughout the low temperature test chamber industry, there are no less than thousands of manufacturers. Almost every family is confident about their products, but from the feedback complaints and after-sales situation of users, Wuxi Guanya Thermo...

세부 정보 보기 -

New energy power car power battery detection system vacuum description

1144The new energy power vehicle power battery test checks the vacuum pump switch in the closed state before operation; when the vacuum pump is placed horizontally, ensure that the lubricating oil and the oil level line are kept horizontal; whether th...

세부 정보 보기 -

배터리 모터 테스트를 위한 고온 및 저온 냉온수 냉각기

1106LNEYA high and low temperature cold and heat integrated water cooler is used in battery thermal management of new energy electric vehicles. The following is the relevant principle applied in thermal management.The high and low temperature cold and...

세부 정보 보기

LNEYA 산업용 냉각기 제조업체 공급 업체

LNEYA 산업용 냉각기 제조업체 공급 업체