Explosion-proof high temperature and low temperature machine factory note

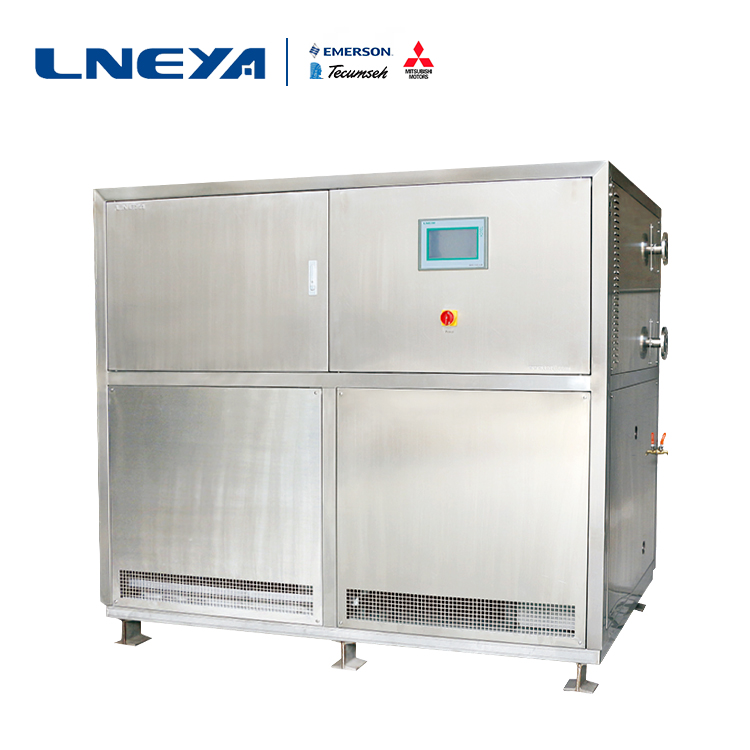

Explosion-proof high and low temperature integrated machine is the main product of LNEYA production and sales. It adopts dynamic temperature control system and fully closed pipeline design. The operation effect is relatively stable. What common problems should be paid attention to during the operation?

Explosion-proof high and low temperature integrated machine should be installed away from heat source, no direct sunlight, good ventilation, and the ambient temperature should not exceed 35 °C to prevent the condenser from dissipating heat and affecting the ice making effect. The installed floor should be solid and flat and must be level, as this will result in no ice detachment and noise during operation.

The explosion-proof high and low temperature integrated machine has a gap of not less than 30cm on the back and left and right sides, and the top clearance is not less than 60cm. Explosion-proof high and low temperature integrated machine should use independent power supply, special line power supply and equipped with fuse and leakage protection switch, and must be grounded reliably. Water should meet the national drinking water standards, and a water filtration device should be installed to filter impurities in the water to avoid clogging the water pipes, polluting the water tank, and affecting the cooling performance.

When cleaning the explosion-proof high and low temperature integrated machine, the power should be turned off. It is strictly forbidden to use the water pipe to directly align with the body. Use neutral detergent to scrub. Do not use acidic or alkaline corrosive solvents. It is necessary to unscrew the inlet hose head two months and clean the inlet valve screen to prevent the sand mud impurities from clogging the water inlet, which causes the water intake to become smaller, resulting in no refrigeration. Explosion-proof high and low temperature integrated machine must clean the surface of the condenser every two months, and poor condensation and heat dissipation will cause damage to the compressor components. When cleaning, use a vacuum cleaner, a small brush, etc. to clean the condensed surface oil dust. Do not use a sharp metal tool to clean it to avoid damaging the condenser.

Water pipes, sinks, storage refrigerators and protective film should be cleaned every two months. When not in use, it should be cleaned, and the ice mold and the moisture in the box should be dried with a hair dryer, and placed in a place free of corrosive gas and ventilated and dry, to avoid open storage. Also need to pay attention to maintenance, pay attention to the strength, do not damage the explosion-proof high and low temperature machine.

관련 권장 사항

-

액체를 100℃까지 가열하고 30℃까지 냉각하는 온도 제어 시스템

1118가열 방법으로는 증기 가열, 열유 가열 등이 있습니다. 증기 가열은 증기 공급이 가능한 공장에 적합한 보일러가 필요할 수 있으며, 열유는 고온에 적합하며 유...

세부 정보 보기 -

How to extend the service life of heat transfer oil in dynamic temperature control system?

1016In the chemical industry, the heat transfer medium of the heat transfer oil of the dynamic temperature control system of the reactor is mainly determined by the heat transfer oil itself, the operating temperature of the heat transfer oil, the dyna...

세부 정보 보기 -

-

산업 등급 냉난방 시스템 배치 주의

1320산업 등급 냉난방 시스템 전원을 켜기 전에 명판에 지정된 전압이 가정용 전압과 동일한지 확인하세요. 별도의 전원 라인과 특수 소켓을 배치하는 데에도 동일하게 사용할 수 있습니다 ...

세부 정보 보기

LNEYA 산업용 냉각기 제조업체 공급 업체

LNEYA 산업용 냉각기 제조업체 공급 업체