반도체 제조 공정에 사용되는 특수 가스에 냉각기가 필요한 이유는 무엇일까요?

If you have any questions, please contact us

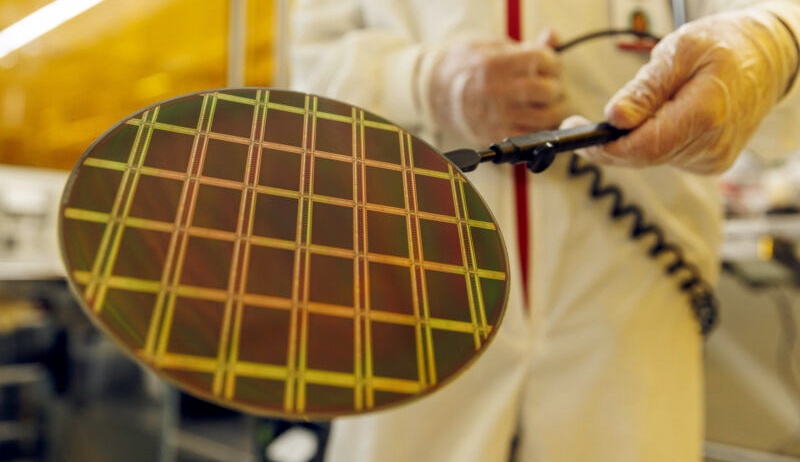

When using special gases in semiconductor manufacturing processes, a chiller is required, mainly due to the following reasons:

- Gas purity control: Special gases are used as raw materials in semiconductor manufacturing, and their purity is crucial to the performance of the final semiconductor device. Some special gases are prone to decomposition or react with impurities such as oxygen and water vapor at high temperatures, reducing their purity. The low-temperature environment provided by the chiller helps maintain the purity of gas during storage and transportation.

- Gas transportation and storage: Some special gases are easy to store in a liquefied state

Transportation, chillers can be used to cool gases to low temperatures, liquefy them, and facilitate storage and metering. Meanwhile, a low-temperature environment is beneficial for slowing down the natural evaporation rate of gases and reducing losses.

3. Process requirements: In semiconductor manufacturing processes such as chemical vapor deposition (CVD), physical vapor deposition (PVD), atomic layer deposition (ALD), etc., gas needs to go through a pre-treatment system, including a cooling system, before entering the reaction chamber to maintain gas transport at a specific temperature and prevent gas preheating or premature reaction in the pipeline.

4. Equipment cooling: Semiconductor production equipment generates a large amount of heat during operation, and requires a chiller to provide cooling for its internal gas delivery pipelines, reaction chambers, and other components to ensure that the gas maintains a stable temperature when entering and leaving the chamber. This is crucial for precise process control and product quality.

5. Safety considerations: Some special gases may become unstable or flammable and explosive at high temperatures. Using a chiller can reduce the risk of gas leakage accidents and ensure the safety of the entire process.

Therefore, the chiller is crucial for the storage, treatment, and use of special gases in the semiconductor manufacturing process, and is one of the key equipment to ensure the smooth progress of the semiconductor manufacturing process.

Request a quote

7 * 24 무료 상담 및 종합 솔루션 제공

관련 권장 사항

-

Selection method of 0℃~5℃ freezing liquid for industrial ultra-low temperature chiller

981As the requirements for process production become higher and higher, industrial ultra-low temperature chillers are required to provide cryogenic liquid below 5 degrees or even more than minus 100 degrees in some chemical process synthesis, reactor...

세부 정보 보기 -

열유 2차 순환 시스템 안전 지식

1167The thermal oil secondary circulation system is equipped with various instruments and equipment for temperature control. After market research, carefully research and production of temperature-controlled products, when using, you need to pay atten...

세부 정보 보기 -

배터리별 온도 사이클 테스트 챔버 냉각기 팁

1072경제의 급속한 발전과 함께 신에너지 자동차 산업도 급속한 발전을 이루었으며 배터리 산업의 요구 사항도 점점 더 높아지고 있습니다. 관련 산업에 적응하기 위해 LNEYA는 ...

세부 정보 보기 -

Why does a chiller need to be installed for cooling the water storage tank?

1040The main reasons for configuring a chiller for cooling the water storage tank are related to the following aspects: Temperature Control: In many industrial and commercial applications, such as air conditioning systems, chemical processes, ...

세부 정보 보기

LNEYA 산업용 냉각기 제조업체 공급 업체

LNEYA 산업용 냉각기 제조업체 공급 업체

상담 신청하기

24시간 이내에 답변 드리겠습니다.