새로운 에너지 테스트를 위한 특수 냉각기 설치 시 주의사항

The installation of the special chiller for new energy testing is an important link before operation. The quality of the installation is directly related to the operation and operation status of the special chiller for new energy testing. So, what should be paid attention to in the installation of the special chiller for new energy testing?

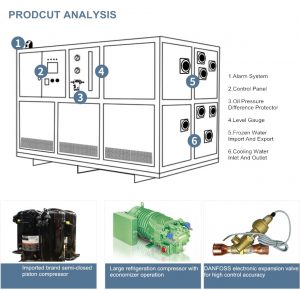

If the special chiller for new energy test adopts semi-hermetic or fully-hermetic compressor, an oil separator should be installed, and an appropriate amount of oil should be added to the installed oil separator. When the evaporation temperature is lower than -15 degrees, a gas-liquid should be installed. Separator and add appropriate amount of refrigeration oil. Secondly, the compressor base should be installed with a shock-absorbing rubber seat, and the installation of the special chiller for new energy testing should leave a maintenance space to facilitate the observation of the adjustment of instruments and valves.

The high pressure gauge of the special chiller for new energy testing should be installed at the tee of the liquid storage and filling valve. The overall layout of the special chiller for new energy testing is reasonable and the color is the same. The installation structure of each type of unit should be consistent.

When debugging the special chiller for new energy test, it is necessary to pay attention to measuring the power supply voltage, measuring the resistance value of the three windings of the compressor and the insulation of the motor, checking the opening and closing of each valve of the refrigeration system, and pouring the refrigerant into the storage liquid to the standard charge after evacuation. 70%-80% of the filling volume, and then run the compressor, add air from low pressure to enough volume.

After the special chiller for new energy test is turned on, first listen to whether the sound of the compressor is normal, check whether the condenser and air cooler are running normally, and whether the three-phase current of the compressor is stable. After the special chiller for new energy test cools down smoothly, check the exhaust pressure, suction pressure, exhaust temperature, suction temperature, motor temperature, crankcase temperature, and expansion valve temperature in the refrigeration system, and observe the frosting of the evaporator and expansion valve. , observe the oil level and color change of the oil glass. Check whether the sound of the special chiller for new energy testing is abnormal.

Another point is that the special chiller for new energy testing needs to pay more attention to its maintenance knowledge and carry out a lot of related maintenance work.

관련 권장 사항

-

Description of power consumption in LNEYA large refrigeration unit

1319In the process of operation, the cooling capacity and working conditions will affect the power consumption of the entire large refrigeration unit, but in order to avoid unnecessary power consumption, we need to understand the other power consumpti...

세부 정보 보기 -

What is the refrigeration principle of the glycol chiller system

1298Glycol Chiller System , as we can tell fromits name, it is to use Glycol as the refrigeration agent for the chiller. In the all air environment, because of thelow temperature in the outdoors, it is impossible to use a cooling tower tosupply t...

세부 정보 보기 -

Industry and introduction of low temperature chiller

1005In petroleum refining, petrochemical industry, organic synthesis, chemical products and other industrial production, refrigeration technology must be applied to control the reaction temperature during processes such as liquefaction, condensation, ...

세부 정보 보기 -

증착 코팅기 온도 제어 시스템-냉각수 시스템

1190The main purpose of the vapor deposition coating machine is to carry out scientific experiments and research on film formation process. It is composed of quartz tube reaction chamber, heat shield furnace cabinet, electrical control system, vacuum ...

세부 정보 보기

LNEYA 산업용 냉각기 제조업체 공급 업체

LNEYA 산업용 냉각기 제조업체 공급 업체