Routine maintenance of tcu multi-reactor temperature control equipment

TCU multi-reactor temperature control equipment is widely used in research departments such as petroleum, chemical, electronic instruments, physics, chemistry, bioengineering, physical property testing and chemical analysis, colleges and universities, enterprise quality inspection and production departments to provide users with a liquid environment with controlled cold and hot, uniform and constant temperature when working.

1. Tcu multi-reactor temperature control equipment is a heating equipment that can control the temperature of the reaction material by heating the heat transfer oil in the jacket of the reactor to transfer heat energy to the material in the reactor indirectly.

2. The whole liquid circulation is a closed system. There is no absorption of water vapor at low temperature and no oil mist at high temperature. The heat transfer oil can work at a wide temperature; The same machine and the same heat conduction medium can realize continuous temperature rise and fall control.

3. Equipped with a heating and cooling integrated container, the heat exchange area is large, the heating and cooling rate is fast, and the demand for heat transfer oil is relatively small. It can realize continuous temperature rise and fall. Refrigeration heat exchanger adopts plate heat exchanger with high heat exchange efficiency and small floor area.

4. It has self-diagnosis function, refrigerator overload protection, high-voltage pressure switch, overload relay, thermal protection device and other reliable guarantee functions, fully ensuring reliable use;

5. In case of power failure, use dry compressed air regularly to clean the inside of the machine’s electric box and heat dissipation dust to avoid electrical failure caused by metal residues falling on the electrical components;

6. During normal use, use dry compressed air regularly to clean the metal residue and dust on the fan cover of the pump inside the machine to prevent the motor from radiating poorly after the fan cover is blocked, which may cause abnormal noise or jamming of the pump motor;

7. During long-term use, regularly maintain or replace other machine parts according to other requirements in the manual. In case of shutdown, regularly clean the filter at the oil return port of the machine to avoid over-temperature alarm and other faults caused by filter blockage; Customers can formulate effective maintenance plans according to the use of the machine and the site environment.

관련 권장 사항

-

How do semiconductor CVD and PVD chillers work?

1101The working principle of the chillers used in semiconductor chemical vapor deposition (CVD) and physical vapor deposition (PVD) processes is mainly to remove the heat generated during the process by circulating cooling water or special coola...

세부 정보 보기 -

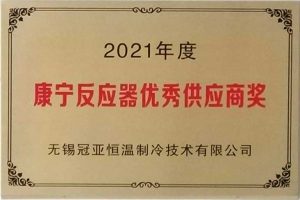

"2021년 원자로 온도 제어 장비 우수 공급업체" 수상

3140미국 포춘지 선정 500대 기업인 코닝이 선정한 '2021 우수 리액터 기술 공급업체'로 선정되었습니다. 2015 년부터 LNEYA는 7 년 연속이 상을 수상했습니다. 따라서 원자로 제조 산업에서 우리는 ...

세부 정보 보기 -

신에너지 차량 검사에서 판형 열교환기의 일반적인 결함

1441새로운 에너지 차량 감지의 과도한 압력 강하의 이유는 실행중인 시스템 파이프 라인이 제대로 퍼지되지 않았기 때문이며, 특히 새로 설치된 시스템 파이프 라인에서 많은 먼지 (예 : 용접 슬래그)가 내부로 유입되기 때문입니다 ...

세부 정보 보기 -

극저온 냉장고 냉장 시스템은 어떻게 배수되나요?

1690Users who use ultra-low temperature chillers will encounter some problems when they are not used for a long time, such as poor cooling performance and loud sound. These problems are more common, but some refrigeration systems need to be well under...

세부 정보 보기

LNEYA 산업용 냉각기 제조업체 공급 업체

LNEYA 산업용 냉각기 제조업체 공급 업체