Description of the principle and mode of industrial water chiller refrigeration cycle

Anyone who knows about industrial water

chillers should know that it uses compressors to achieve the cooling effect.

So, how does it work when refrigerating?

1. Vapor compression refrigeration cycle.

After cooling and pressurizing the vapor

from the evaporator, it is recondensed into a liquid, and then evaporated

again, so that it continues to circulate, which is the vapor compression

refrigeration cycle. Industrial water chillers adopt this refrigeration method,

and the principle of vapor compression refrigeration cycle is realized in this

way.

Fill the industrial water chiller with the

refrigeration medium in a sealed system. After the liquid working fluid is

throttled and depressurized by the throttling device, it will vaporize and

absorb heat at the middle pressure in the evaporator to become low-temperature

and low-pressure steam, and then pass through the compressor. Adiabatic

compression into high temperature and high pressure steam, liquefaction in the

condenser to release heat, and then enter the throttling device, thus

completing a refrigeration cycle.

2. Absorption refrigeration cycle.

The absorption refrigeration cycle utilizes

the heat energy provided by the heat source to make the working medium

circulate. Its working principle is as follows: it replaces the compressor with

components such as absorber and generator, and uses two working mediums. The

working medium with low boiling point is called refrigerant The high boiling

point working fluid is called absorbent, and the functions and principles of

other components are basically the same as the vapor compression refrigeration

cycle.

There are two loops in the absorption

refrigeration cycle of industrial water chillers. Its working process is: after

the liquid refrigerant is throttled and reduced by the throttling device, it

evaporates and absorbs heat at the middle pressure in the evaporator and

becomes low-pressure, low-temperature refrigerant vapor. After entering the

absorber, it is strongly absorbed by the absorbent to form a high-concentration

refrigerant solution and release heat of dissolution. Then the refrigerant

solution in the equipment is pumped into the generator, heated by the heat

source to produce high-pressure refrigerant vapor, which is sent to the

condenser to be condensed into liquid refrigerant, and the remaining dilute

solution in the generator is decompressed Back to the absorber.

Summarize

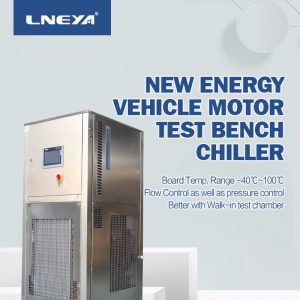

Wuxi Guanya (LNEYA) adopts environmentally

friendly refrigerants for the refrigeration operation of industrial water

chillers, in an environmentally friendly environment, in line with the

development theme of the current environment. Global consulting sales@lneya.com

관련 권장 사항

-

Manufacturer analysis – 90 ° C single-stage refrigeration system compressor common form

1208There are many types of compressors in the -90 °C single-stage refrigeration system. The most used ones are the piston refrigeration compressors. So, do you know which types? In the refrigeration system industry, the more commonly used refrigerati...

세부 정보 보기 -

Energy storage system requirements for temperature-controlled liquid-cooled unit

1492Energy storage system: It needs to meet the discharge demand for a long time. It is suitable for energy storage on the side of new energy generation, arbitrage of peak-valley price difference on the user side, etc. The future trend is that...

세부 정보 보기 -

김이 나는 시스템 온도 제어 안전 요구 사항

1186김이 나는 시스템 온도 제어는 우시 구아냐 엘네야에서 설계하고 생산한 저온 냉장고 중 하나입니다. 온도 범위는 -5°C에서 -150°C입니다. 2 차 과냉각 기술이 채택되고 냉동은 ...

세부 정보 보기 -

What do you need to consider for a car battery cooling water cycle heat exchanger?

991The car battery cooling water circulation machine has always been one of the most popular equipments. The design of the heat exchanger piping also needs to be designed. What aspects should be considered? There are many types of heat exchange equip...

세부 정보 보기

LNEYA 산업용 냉각기 제조업체 공급 업체

LNEYA 산업용 냉각기 제조업체 공급 업체