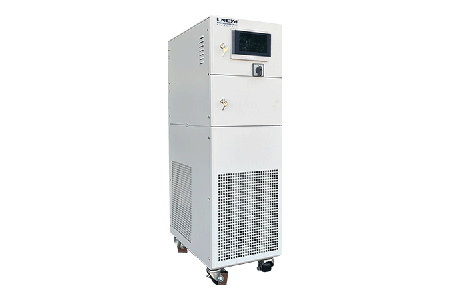

모든 순환 냉각기 모델

LT 10℃~30℃

냉각기 기계

냉각 용량 3kW~14kW

순환 펌프 유량 30L/min 1.6bar~50L/min 2bar

LT -25℃~30℃

냉각 순환기

냉각 용량 1kW~5kW

순환 펌프 유량 30L/min 1.6bar

온도 정확도 ±0.5℃

LT -45℃~30℃

냉각 순환기

냉각 용량 0.7kW~4.8kW

순환 펌프 유량 30L/min 1.6bar

온도 정확도 ±0.5℃

LT -60℃~-30℃

냉장 순환기

냉각 용량 0.7kW~4.8kW

순환 펌프 유량 30L/min 1.6bar

온도 정확도 ±0.5℃

LT -80℃~-40℃

폐쇄 루프 냉각기

냉각 용량 0.4kW~2.5kW

순환 펌프 유량 30L/min 1.6bar

온도 정확도 ±0.5℃

LT-800 -18~30℃

미니 칠러

냉각 용량 0.35kW~0.9kW

순환 펌프 유량 10L/min 0.6bar

LNEYA 산업용 냉각기 제조업체 공급 업체

LNEYA 산업용 냉각기 제조업체 공급 업체