진공 펌프 온도 제어 시스템 사용에 대한 오해

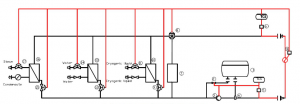

When using the vacuum pump temperature control system, only the correct operation method can ensure the normal and stable operation of the equipment. If there are many wrong operation behaviors, it will directly affect the normal use of the equipment, and even affect the cooling performance.

1. When starting up, adjust the pressure drop of the inlet and outlet water higher than the operating parameters. When the pressure drop is too high, open the inlet and outlet valves of the evaporator of another non-operation unit. Reduce pressure drop by draining excess water from another unit evaporator. This mode of operation is artificially increasing the running current of the cold water pump, wasting power resources.

2. When starting up, the inlet and outlet valves on the evaporator of the chiller that are not turned on are not closed first, which causes a part of the cold water to flow away from the evaporator of the chiller that is not turned on, which affects the cooling effect of the chiller in the working state.

3. In the process of operation, it is necessary to carefully study the specific steps of opening and closing the equipment, and use the correct operation method to start the heating and cooling temperature control system according to the actual use environment, so as to avoid equipment failure.

4. Every time you need to use it, you need to follow the steps in the instruction manual. If there is a different operation method than the requirement, it needs to be corrected in time, so as not to affect the normal operation of the equipment, and it is not conducive to the long-term use of the vacuum pump temperature control system by the enterprise.

Therefore, when using it, you need to learn the correct operation method. If the enterprise can complete the entire operation process of the vacuum pump temperature control system according to the operating instructions, even without any maintenance and maintenance, the service life of the equipment can also be guaranteed. Then the more failures occur, the higher the cost of use, which is not conducive to the long-term completion of production tasks for enterprises.

In terms of industrial process temperature control, no matter which temperature control system/equipment you use, they are actually chillers. The difference is that water is used as the cooling cycle or oil is used as the medium. temperature unit. Need help find our LNEYA temperature control solution department at sales@lneya.com.

관련 권장 사항

-

How to avoid improper operation of heating and cooling circulator?

1085When the user runs the heating and cooling circulator, the operation needs to follow the instructions. Then, how to avoid unsuitable operation? LNEYA heating and cooling circulator has multi-function alarm system and safety function. It uses plate...

세부 정보 보기 -

화학 합성 공정 제어 시스템 온도 제어 시스템 TCU

1169오늘은 DCS 통합 제어 시스템(합성 공정의 온도 및 기타 제어)에 대해 이야기해 보겠습니다. 확장성: 이 시스템은 개방형 시스템으로 표준 TCP/P 데이터 통신 인터페이스 프로토콜, 인터페이스 소프트웨어 및 ...

세부 정보 보기 -

Advantages of Cold Plate Freezer

1033The freezing method is mainly used when the capacitive liquid crystal touch panel of smartphones and tablet computers has defects in production, such as bubbles, foreign objects, black spots, white spots, misplaced..., and needs to be used for rew...

세부 정보 보기 -

40GW 극저온 냉각기의 유형 선택 및 분류에 대한 설명

1184If different enterprises and different industries have different requirements for Wuxi Guanya 40GW cryogenic chillers, its model selection is also different. So it is better to have a clear understanding of the needs of the selection of 40GW cryog...

세부 정보 보기

LNEYA 산업용 냉각기 제조업체 공급 업체

LNEYA 산업용 냉각기 제조업체 공급 업체