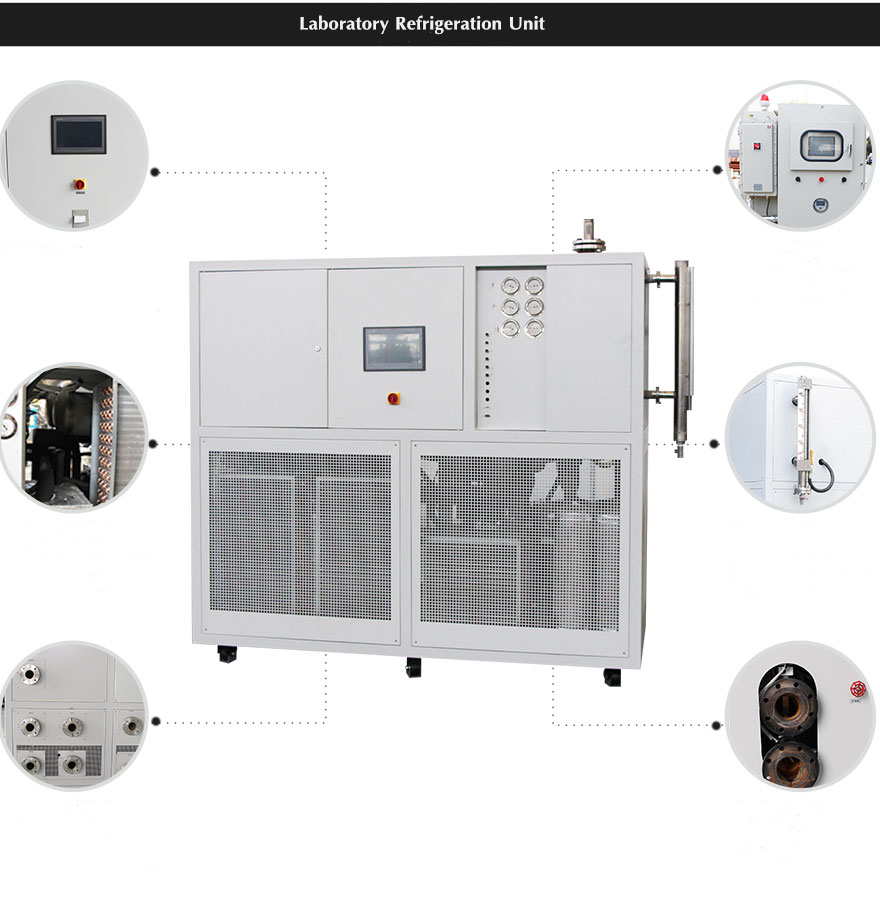

실험실 기기용 특수 냉장 장치의 일상적인 유지보수 포인트

Industrial refrigeration units dedicated to laboratory instruments are used more in the pharmaceutical and chemical industries, and care must be taken when using them.

The daily maintenance of the industrial refrigeration unit dedicated to experimental instruments is mainly reflected in the following aspects:

1. Condenser

The high-temperature and high-pressure Freon of the refrigeration system of the industrial refrigeration unit dedicated to the experimental instrument comes out of the compressor and enters the condenser, releasing a large amount of heat to the cooling medium and being liquefied by the cooling.

If the industrial refrigeration unit dedicated for laboratory instruments has been used for more than half a year, or the high and low pressure engines frequently fail, or the cooling capacity is reduced, please arrange a technician to clean the condenser. The fin condenser is generally cleaned with a high-pressure water gun. Be careful not to clean it sideways, which can easily cause the fin to fall over. Shell-and-tube condensers are generally immersed and circulated with descaling chemicals, and then the end cover is opened, and the pipes are cleaned one by one with a gun gun. Cleaning the condenser can significantly improve the refrigeration efficiency of the industrial refrigeration unit dedicated to laboratory instruments.

2. Compressor

Every time the compressor operating time of the industrial refrigeration unit dedicated to the experimental instrument exceeds one thousand hours, all details of the compression equipment should be checked. For example: whether the lubricating oil is normal; whether the running current of the compressor is normal; whether there is any abnormality when the compressor is running. Of course, the current refrigeration technology is quite mature, there are many sensors and protectors. When the unit alarms the fault, it should be repaired according to the fault location. When the compressor makes abnormal noise when it is running, it should be shut down for maintenance, mostly due to insufficient lubricant.

3. Refrigerant

The industrial refrigeration unit dedicated to experimental instruments is an indispensable equipment for industrial production now, and each unit is inseparable from the participation of refrigerant, so the lack of refrigerant will affect the normal operation of the machine and will appear The cooling capacity of the industrial refrigeration unit dedicated to the experimental instrument is insufficient, or the cooling temperature is very slow.

Routine maintenance cannot be ignored. Effective maintenance can keep the industrial refrigeration unit dedicated to laboratory instruments in an effective state of operation.

관련 권장 사항

-

Product features of explosion-proof high and low temperature machine

1339LNEYA explosion-proof high and low temperature machine is a relatively temperature control equipment that can be used in the current heating and cooling system. It can be used for simultaneous cooling and heating. It can be combined with various r...

세부 정보 보기 -

40 스크류 냉동고의 기밀성을 확인하는 방법은 무엇인가요?

1281기밀성은 전체 40 핀 스크류 냉동고의 냉각 효과와 관련이 있습니다. 따라서 LushiA (LNEYA)의 40 핀 스크류 냉동고 제조업체는 사용자에게 4 가지 검사를 수행 할 것을 권장합니다. 이 테스트는 ...

세부 정보 보기 -

신에너지 차량 품질 테스트를 위한 KRY 시리즈 수냉식 냉각기

1064새로운 에너지 차량 파워트레인 테스트 벤치는 하프샤프트를 통해 전기 구동 어셈블리의 동력 출력단에 직접 연결할 수 있습니다. 프런트 엔드에는 고정밀 토크 센서와 속도 센서가 장착되어있어 높은 정밀도를 제공합니다.

세부 정보 보기 -

2018 Automotive Testing Expo

10252018 Automotive Testing Expo (2018 Automotive Testing and Quality Control Expo) is China's relatively large vehicle and component testing and verification technology and service exhibition. Wuxi Guanya LNEYA is committed to developing battery te...

세부 정보 보기

LNEYA 산업용 냉각기 제조업체 공급 업체

LNEYA 산업용 냉각기 제조업체 공급 업체