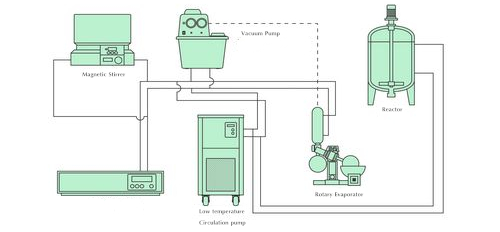

Low-temperature coolant circulation pump used with rotary evaporator

The chemical and pharmaceutical fields are the largest end consumer markets for cryogenic coolant circulation pumps. With the increasing demand for low-temperature coolant circulation pumps in this market, the application of cryogenic pumps in the chemical industry is becoming more mature. As a laboratory instrument, cryogenic coolant circulation pumps are indispensable to the laboratory field. It plays an important role in chemical, pharmaceutical and chemical research.

The low-temperature coolant circulation pump can directly cool test tubes, reaction flasks, etc. to carry out chemical reactions at low temperatures, and carry out low-temperature storage of chemicals and biological products. It can also be used in conjunction with rotary evaporators, vacuum freeze-drying boxes, circulating water-type multi-purpose vacuum pumps, etc.

One low temperature coolant circulation pump with two rotary evaporation laboratory cases Note points:

When in use, the actual temperature should not be lower than the minimum temperature. If water is used as the circulating solution, the water inlet pipe cannot be higher than 60 degrees Celsius, but when using absolute ethanol, the water inlet can not be higher than 10 degrees Celsius.

Lneya low-temperature coolant circulation pump adopts international brand compressor, which has small volume and high efficiency. Single compressor can achieve -152°C temperature control. The shell material is cold-rolled steel plate, and the circulating pump with pressure ≤6bar can be customized to make the liquid storage larger capacity according to the needs. Exclusive self-cascade supercooling refrigeration technology, in order to save water resources, can use ethylene glycol-water mixture for circulating refrigeration, strict circulation pipeline design, prevent circulating water pollution, extend the circulating water use time; -125 ° C ~-20 °C Wide temperature range; adjustment unit 0.1 degree. Ambient temperature monitoring function is provided to prevent damage to the system when the ambient temperature is too high.

관련 권장 사항

-

Necessity of temperature control in fractional distillation of distillation

1008The pharmaceutical and chemical industry involves many chemical reactions, and with the continuous development of the pharmaceutical and chemical industry, there is a great demand for such instruments. The traditional open cooling and heating con...

세부 정보 보기 -

화학 및 제약 반응기에서 온도 제어 시스템 TCU의 역할

1342의약품 연구 개발 및 화학 실험에서 반응 케틀의 온도 제어는 물론 소규모 실험 생산 및 산업 생산 공정의 온도 제어에는 매우 동적 인 온도 제어가 필요합니다.

세부 정보 보기 -

고온 환경 챔버 판매의 설계 및 테스트 기술

13101. 온도 선택 (1) 해당 지역의 기후대, 제품이 난방 장치 근처의 태양 복사 환경에 노출되는지 여부, 주변 공기, 태양 복사 및 난방 장치에서 제품으로의 열 전달 방식...

세부 정보 보기 -

차량 고온 및 고습 테스트 차량 노화 방지 성능 테스트

1083On test benches in the automotive industry, accurate temperature simulation is critical. From the time of the test, the air temperature in the test chamber has always been maintained at 45 ℃, which is equivalent to the hottest area of the Flaming...

세부 정보 보기

LNEYA 산업용 냉각기 제조업체 공급 업체

LNEYA 산업용 냉각기 제조업체 공급 업체