Troubleshoot the main points of failure of the high and low temperature cooling system

When the industrial high and low temperature cooling system is in use, what is the general reason if the temperature cannot drop down? How should we deal with such failures?

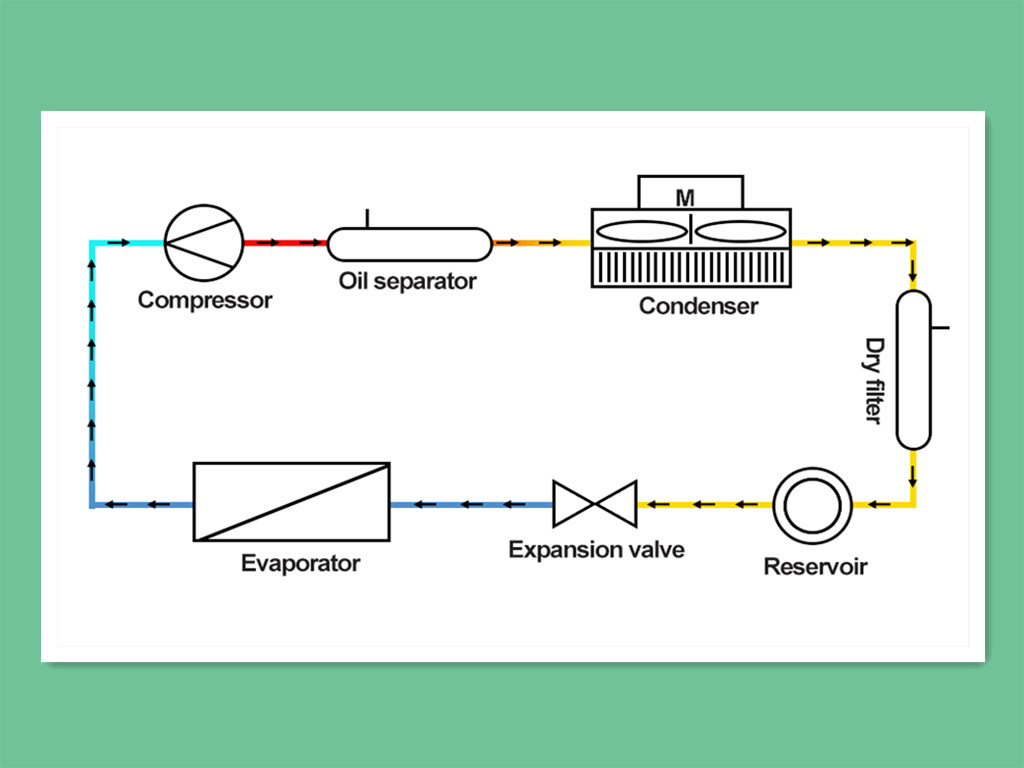

Let’s first analyze the principles and methods of industrial cooling. The circulating heat transfer medium is different. Generally, the high and low temperature cooling system industry mostly uses direct cooling, while indirect cooling is used, with plate heat exchangers or oil coolers installed inside. In other devices, the heat medium and cooling water source in the system exchange heat in the heat exchanger to reduce the temperature of the medium.

The temperature of the high and low temperature cooling system cannot be reduced. Generally, we conduct inspection and maintenance from the following aspects:

1. The cooling solenoid valve is damaged: it is necessary to check whether the solenoid valve coil can work normally, if it is damaged, it needs to be replaced; the panel does not output a cooling signal, carefully check the circuit or use the component replacement method to check.

2. Circuit failure: Check the circuit part of the system, the cooling water inlet or outlet pipeline is blocked: check whether the valve in the cooling water pipeline is fully opened, and ensure that the flow and pressure of the cooling water are sufficient, and the heating contactor is stuck, Always heating: observe the pull-in state of the contactor, and worsen damaged electrical parts.

In addition to troubleshooting the above two possible causes of failure, we also need to check whether the cooling plate is replaced or the cooling exchanger is blocked.

The advantage of using indirect cooling is that it has high temperature control accuracy and strong adaptability. It can be applied to the temperature control of high and low temperature cooling system industries. And because the heat transfer medium is cooled first, the cooling impact on the temperature control equipment is relatively small. Of course The disadvantage is that the cooling speed is relatively slow, and the price is more expensive than direct cooling.

관련 권장 사항

-

저온 순환 장치의 프로스팅을 해결하는 방법은 무엇입니까?

1388저온 순환 장치 프로스팅의 고장은 주로 압축기 복귀 공기 온도가 너무 낮기 때문에 스로틀 밸브 액체 냉매 공급이 저온 순환 장치에서 정상 상태 일 수 있습니다 ...

세부 정보 보기 -

New energy vehicle quality test water cooling chiller simulation equipment

922It is mainly used in the water cooling system stability test of new products such as electric drives, motors, reducers, and charging piles of new energy vehicles. Constant temperature, constant pressure and constant current heat test (5-85°C), h...

세부 정보 보기 -

Advantages and disadvantages of water-cooled chillers

1130The water-cooled industrial chillers produced by LNEYA are refrigeration equipment that provides chilled water. Today we will discuss the classification, advantages and disadvantages of water-cooled chillers. Water-cooled chiller configuration: 1....

세부 정보 보기 -

LNEYA: 모든 디테일을 디자인하는 데 집중하여 멋진 작품을 만들 수 있습니다.

1192LNEYA는 냉장 및 난방 온도 제어 분야의 뛰어난 인재를 활용하고 있으며 강력한 기술 배경을 보유하고 있습니다. 업계에서 잘 알려진 하이엔드 R&D 팀을 보유하고 있습니다. 그것은 하이 엔드 R & D 및 응용 프로그램 팀입니다 ...

세부 정보 보기

LNEYA 산업용 냉각기 제조업체 공급 업체

LNEYA 산업용 냉각기 제조업체 공급 업체