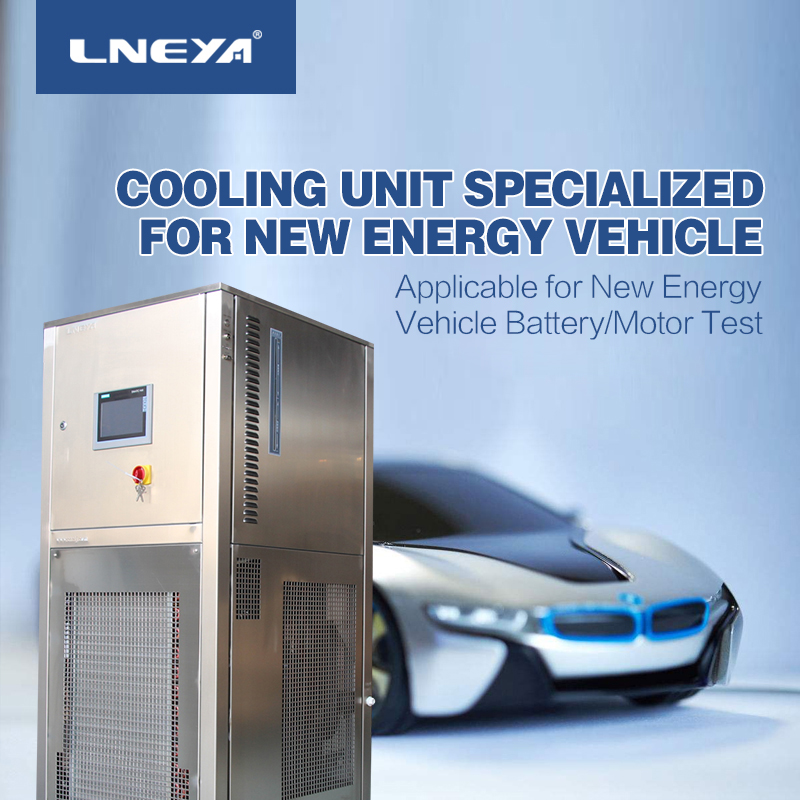

Motor test bench environmental cabin option for new energy vehicles

Passenger car motor and commercial vehicle motor test bench can complete the stall torque and locked rotor current test, temperature rise test, continuous electric working characteristic test, motor maximum speed test, motor over speed test and feed operation characteristic test. At the same time, the test bench can feed the electricity generated during the test to the company’s power grid through the frequency conversion system.

Motor labs and performance dynamometers must contain functions that control the stimulating elements of the application, the most difficult of which is usually temperature cycling. Many systems are designed to be propelled into the environmental chamber and, if necessary, shield any sensitive power tool test components from extreme temperatures or humidity.

The measurement and control system consists of a host computer monitoring system, a data acquisition system, a sensor measurement system, a frequency converter control system, a test bench auxiliary equipment control system, a safety monitoring system, and an early failure warning system. The measurement and control system uses a real-time bus as the main communication network and a CAN bus that communicates with the device under test. The upper computer monitoring system communicates with the data acquisition system and the inverter control system through real-time bus, dynamically controls the motor in real time, collects the data of each sensor at high speed, and analyzes and processes the data. The lower computer controller communicates with each auxiliary test system, and controls the auxiliary test system, and simultaneously collects the sensor data of each safety monitoring, such as: motor temperature, bearing temperature, coolant temperature, cooling pressure, etc.; The DI/DO interface controls, for example, the system issues an emergency stop command, and the lower controller immediately outputs the corresponding DO signal to cut off the power of the corresponding system to ensure system safety.

LNEYA new energy battery motor test temperature control system KRY equipment is widely used in the industry, one can connect multiple test equipment at the same time, achieve precise temperature control, and do not interfere with the temperature control process.

(Some of the content comes from the Internet. If there is any infringement, you can contact and modify it, thank you!)

관련 권장 사항

-

-80 °C refrigerator manufacturer operating equipment points

988When the user chooses the -80 °C refrigerator, it is definitely necessary to have a reliable quality. Wuxi Guanya (LNEYA)-80 °C refrigerator should pay attention to its operation details during operation to avoid equipment failure caused by improp...

세부 정보 보기 -

How to troubleshoot the failure of the material aging test chiller?

1100Regular maintenance work for the material aging test chiller, and troubleshooting is also very important. 1. Exhaust at double high pressure, heat dissipation may be problematic. When it is detected that the high and low pressure of the system are...

세부 정보 보기 -

저온 냉각기의 방열 불량에 대처하는 방법

1248저온 냉각기 제품은 다양한 산업 생산에 많은 기여를 하는 동시에 산업 생산의 노동 효율성을 향상시키는 데 도움이 됩니다. 중국 경제의 발전과 생산 공정 요구 사항의 개선으로 ...

세부 정보 보기 -

The Use of Electronic Expansion Valve in Low Temperature Chiller Systems

1198In the low temperature chiller system, the electronic expansion valve plays a key role in controlling the operating power of the system in cooperation with compressors, condensers, evaporators, water-cooled screw chillers, air-cooled screw chiller...

세부 정보 보기

LNEYA 산업용 냉각기 제조업체 공급 업체

LNEYA 산업용 냉각기 제조업체 공급 업체