What are the influencing factors of the industrial refrigerator with minus 200 degrees?

In order to better use the industrial refrigerator with a temperature of minus 200 degrees, you need to understand some influencing factors and how to avoid it.

The oil temperature will have an important effect on the viscosity of the industrial refrigerator with a temperature of minus 200 degrees. If the oil temperature is too low, the viscosity of the oil will increase, the fluidity will decrease, and it will not easily form a uniform oil film, so the expected lubrication effect cannot be achieved. It will also cause the flow speed of the oil to decrease, the lubrication amount to decrease, and the power consumption of the oil pump to increase; if the oil temperature is too high, the viscosity of the oil will decrease, and the oil film will not reach a certain thickness, so that the running parts are difficult to withstand the necessary working pressure. The deterioration of the lubrication condition and the intensification of the wear of the moving parts caused the failure of the -200 degree industrial refrigerator.

It is the guarantee that the industrial refrigerator oil of minus 200 degrees is driven by the oil pump and needs to overcome the flow resistance in the oil system pipeline to each working part. Without sufficient oil pressure difference, there is no guarantee that the lubrication system has sufficient lubrication and cooling oil and the power required to drive the energy regulating device. Therefore, the oil pressure difference of the industrial temperature of the minus 200 degree industrial refrigerator must be within a reasonable range. In order to fully lubricate and cool the moving parts of the unit, the energy adjustment device can be flexibly operated.

The height of the refrigerator oil level refers to the liquid level of the lubricating oil in the oil storage container. The oil storage container is provided with an oil level display device. Generally, the oil level in the oil storage container should be located at the lower position of the horizontal line of the mirror. The purpose of specifying the height of the oil level is to ensure that the amount of oil required to form the oil circulation is sufficient when the pump is in operation. If the oil level is too low, it may cause the pump to be insufficient, causing malfunction or damage to the equipment.

Try to avoid some operational errors in use, resulting in unavailability, but also need to understand the influencing factors.

관련 권장 사항

-

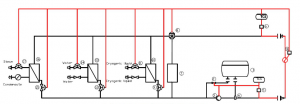

화학 합성 공정 제어 시스템 온도 제어 시스템 TCU

1170오늘은 DCS 통합 제어 시스템(합성 공정의 온도 및 기타 제어)에 대해 이야기해 보겠습니다. 확장성: 이 시스템은 개방형 시스템으로 표준 TCP/P 데이터 통신 인터페이스 프로토콜, 인터페이스 소프트웨어 및 ...

세부 정보 보기 -

전기 도금 폐가스 처리를 위한 파이프 라인의 품질을 판단하는 방법은 무엇입니까?

1055Generally, when purchasing the electroplating waste gas treatment equipment, it is necessary to observe the appearance of the copper tube to judge. The first is to look at the color of the copper tube. According to the type of copper tube purchase...

세부 정보 보기 -

저온 냉각기의 부품 분석

1195The low temperature chiller is a cooling water equipment which is widely used. So, when using it, you should first understand the principle of the cryogenic water chiller and its accessories, so as to run the cryogenic water chiller more efficient...

세부 정보 보기 -

공냉식 냉각기의 고장 코드는 무엇을 의미합니까?

1247일반적으로 기기의 제어판에는 PV 영역과 SV 영역의 두 가지 영역이 표시됩니다. 전자는 특정 온도를 표시하고 후자는 온도 설정을 위한 영역입니다. 오류가 발생하면 PV는 ...

세부 정보 보기

LNEYA 산업용 냉각기 제조업체 공급 업체

LNEYA 산업용 냉각기 제조업체 공급 업체