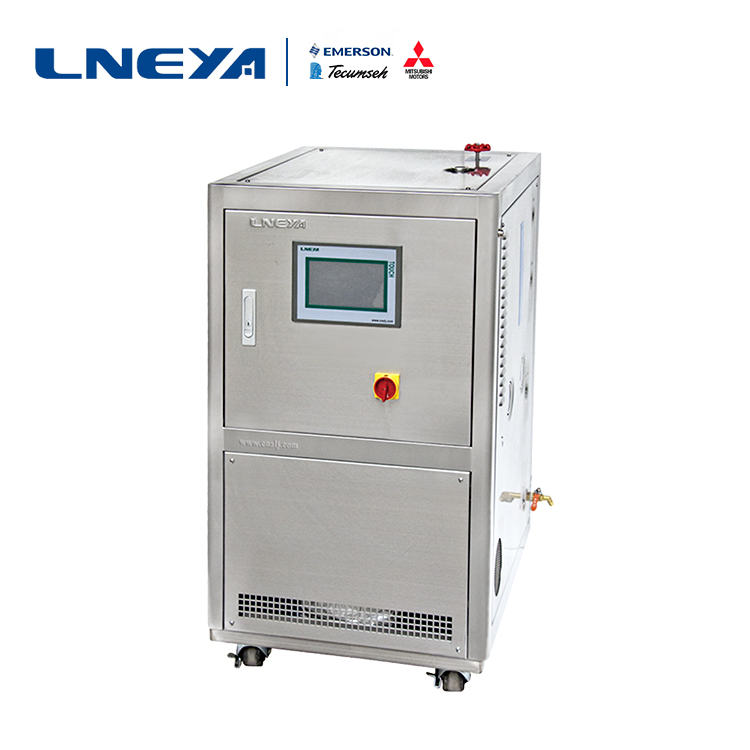

소형 온도 제어 시스템 장비 용접 유지보수 주의사항

소형 서모 스탯 제어 시스템 장비는 수리시 비교 지점에주의를 기울이고, LNEYA 전문 제조업체는 용접 부분도 유지 보수의 핵심 포인트 중 하나라고 상기시킨 다음 어떤 측면에주의를 기울여야하는지 상기 시켰습니다 ...

When the small-scale thermostat control system equipment is welded, protective measures should be taken for the chassis and various components to prevent the flame from being burned by the torch. When welding, pay attention to the adjustment of the torch flame. When the flame is adjusted to the neutral flame, it can be welded. The speed should be as fast as possible to avoid damage to the compressor, the refrigeration valve body and the copper pipe.

If the copper tube is black after soldering, it should be adjusted to increase the flux flow until the copper tube is purple after soldering. When replacing the plate heat exchanger, the welding point should be soaked in water below the welding point, and the plate should be welded with a silver electrode containing 50% silver. It is forbidden to directly weld the plate heat exchanger without taking insulation measures, otherwise the temperature will be too high. After damage, after welding, it must be insulated with insulation board to prevent surface condensation. When installing, the inlet end is at the bottom and the outlet end is at the top.

The compressor of the small constant temperature control system equipment must not be placed horizontally or inverted during the handling of the compressor, otherwise the lubrication performance of the sliding part will be reduced and the compressor will be damaged when it starts. The inclination with respect to the horizontal state shall not exceed 5 degrees, and shall be welded into the system as soon as possible after the rubber stopper is removed, and the time is controlled within 10 minutes. When replacing the capillary, the length of the capillary cannot be increased or decreased arbitrarily, and when the length of the capillary is increased, an unfavorable situation will occur. When the copper tube and the capillary tube are connected, the capillary insertion depth is controlled to be about 10 mm, and the assembly gap of the copper tube brazing is 0.05 to 0.15 mm on one side.

The welded part is very important, and at the same time, it is necessary to pay attention to the strengthening of the process part. The welded part should be found by professional technicians for welding.

관련 권장 사항

-

Transmission powertrain cooling system with evaporator

1025The evaporator is one of the four major components of the refrigeration system, and it is the ultimate embodiment of the refrigeration effect and efficiency. The evaporator is generally designed and equipped by the transmission powertrain cooling ...

세부 정보 보기 -

Meet at booth 6002 of Shanghai World Expo Hall【Testing Expo】9.14-9.16

952Exhibition name: Shanghai International Automobile Testing and Quality Control ExhibitionExhibition time: September 14-16, 2020Booth number: 6002Exhibition address: Shanghai World Expo Exhibition Hall, Hall 1,

세부 정보 보기 -

최적의 냉각기 솔루션을 선택하는 방법은?

1007Choosing a water chiller is like finding a "target" for an enterprise's production equipment. It must not only be "like-minded", but also "be well-matched". The one that suits you is the best. If the choice is not good, either the cooling effect ...

세부 정보 보기 -

What are the effects of the oil separator on the equipment analyzed by the chiller manufacturer

909Oil separators use more accessories in thechiller refrigeration system. So as users, we need to understand where the mainimpact is in order to better use the equipment.In the configuration of the chiller, theposition of the oil separator is aft...

세부 정보 보기

LNEYA 산업용 냉각기 제조업체 공급 업체

LNEYA 산업용 냉각기 제조업체 공급 업체