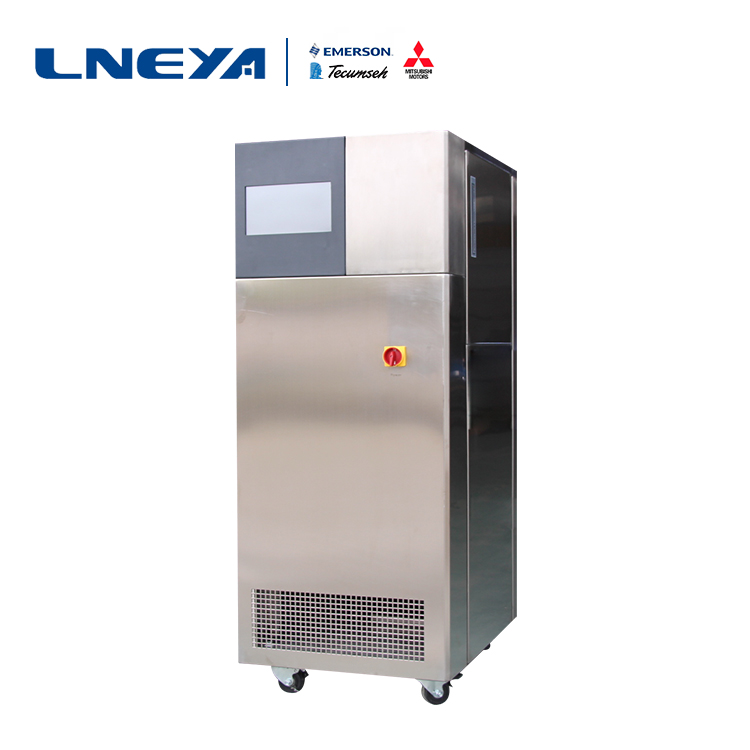

순환 유체 온도 제어 장치의 보호 장치 세부 정보

The circulating pump overload protection function is to cut off the main power of the circulating pump when the circulating liquid temperature adjustment device is too large. Press the green button when resetting; the red button is the stop button, which is used during the test. When frequent protection, please check whether the voltage is under voltage (undervoltage is less than 15%, the power protector is not working), undervoltage is increased into current, forming protection. At this time, a Phillips screwdriver can be used to adjust according to the “△” direction. Current.

Different circulating fluid temperature adjustment devices are equipped with different high and low voltage protectors. The high and low pressure protectors will protect the compressor with reference to the suction and exhaust pressure of the compressor to ensure the normal operation and operating life of the compressor. The high and low voltage protectors are divided into mechanical and electronic high and low voltage protectors. When the high and low voltage protectors are protected, manual reset is required. Press the red highlight button to reset. When the high and low voltage protectors generate protection, manual reset is required. Push the red arrow to reset. The electronic high and low voltage protector is automatically reset.

The circulating fluid temperature adjustment system provides a lot of accessories for equipment protection to ensure the safety and stability of the equipment. The over temperature protection has an independent high temperature temperature limit switch, which can set a relatively large temperature value through this temperature switch (please note) Meet the relatively large operating temperature range of the equipment and the temperature range of the heat transfer oil).

Inspiratory temperature protection with independent compressor suction temperature protector to protect the compressor from excessive suction temperature, ensure that it is within 65 °C (non-recycling liquid temperature adjustment device manufacturer authorization, do not modify, will directly affect the compressor Cooling capacity).

Circulating fluid temperature adjustment device The oil pressure difference protector is generally applied in large equipment. Depending on the equipment, the oil pressure difference protector is different. Press the upper ink green button when resetting. Other types of oil pressure difference protectors are similar. The reset button can be reset by itself. Other protections of the circulating fluid temperature adjustment device include phase protection, phase loss protection, overvoltage and undervoltage protection, leakage protection, and water shutoff protection.

The protection devices of different circulating liquid temperature adjustment devices are different. No matter what brand, the safety devices are more important. We need to pay attention to them. We must carefully check before purchasing to ensure the operation of the equipment.

관련 권장 사항

-

What are the effects of the oil separator on the equipment analyzed by the chiller manufacturer

912Oil separators use more accessories in thechiller refrigeration system. So as users, we need to understand where the mainimpact is in order to better use the equipment.In the configuration of the chiller, theposition of the oil separator is aft...

세부 정보 보기 -

How to extend the service life of heat transfer oil in dynamic temperature control system?

1016In the chemical industry, the heat transfer medium of the heat transfer oil of the dynamic temperature control system of the reactor is mainly determined by the heat transfer oil itself, the operating temperature of the heat transfer oil, the dyna...

세부 정보 보기 -

보조 냉난방 서큘레이터의 전망

1004기업의 지속적인 발전과 함께 라드에 사용되는 매칭 장비로서 제조업체의 브랜드 역할을하는 난방 냉각 순환기는 시장에서 번영하여 지속적으로 요구 사항을 가속화 할 것입니다. 다시 ...

세부 정보 보기 -

500리터 용량의 냉난방 온도 제어 장비에 대한 요구 사항은 무엇인가요?

980The 500-liter reaction kettle cooling and heating temperature control equipment is a dynamic temperature control system, a fully closed circulation pipeline, which can be automatically heated or cooled according to the process requirements. 1. A s...

세부 정보 보기

LNEYA 산업용 냉각기 제조업체 공급 업체

LNEYA 산업용 냉각기 제조업체 공급 업체