High precision semiconductor incubator maintenance instructions

The high-precision semiconductor incubator is in the state of the evaporator as a gas refrigerant; after the adiabatic shrinkage of the shrinking machine, it becomes a high-temperature and high-pressure state, and the contracted gas refrigerant is condensed in the condenser by equal pressure, and is converted by condensation. The liquid refrigerant is expanded into a low pressure through a throttle valve to become a gas-liquid mixture. The liquid refrigerant at low temperature and low pressure absorbs the heat of the cold material in the evaporator, and changes from the head to the gaseous refrigerant. The gaseous refrigerant enters the shrinking machine through the pipe and starts the new cycle. This is the high-precision semiconductor thermostat reincarnation. Four processes.

The high-precision semiconductor thermostat sealing part is nursed back. Since the assembled high-precision semiconductor thermostat is made up of several pieces of insulation board, there is a necessary gap between the boards. In the construction, such gaps are sealed with sealant, in order to avoid air. And the water comes in, so in the use of some parts of the seal is not repaired in real time.

High-precision semiconductor incubator ground nursed back, usually the surface of the small-assembled high-precision semiconductor incubator uses thermal insulation board. When using high-precision semiconductor incubator, in order to avoid a large amount of ice and water on the ground, if there is ice, it must not be processed. Use hard objects to knock and damage the ground.

High-precision semiconductor incubators are used after assembly or long-term deactivation. The rate of cooling should be appropriate: daily operation at 8-10 °C is appropriate, and should be retained for a period of time at 0 °C.

High-precision semiconductor thermostat library board nursery, pay attention to the use should pay attention to the collision and scratching of the hard object on the library, in view of the possibility of becoming the concave and rust of the library board, it will seriously reduce the surface insulation function of the library.

The maintenance of high-precision semiconductor incubators is inseparable from the careful operation of our operators, so we should be kind to our equipment in daily operations, not too rough.

관련 권장 사항

-

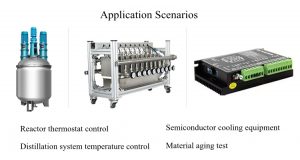

Application Of Jacketed Reactor Cooling And Heating System In Chemical Reactions

1089In the chemical industry, jacketed reactor cooling and heating devices are widely used in various chemical reactions. Application of jacketed reactor cooling and heating devices in various chemical reactions: Polymerization is a c...

세부 정보 보기 -

Do new energy vehicle motor tests require a chiller or heater?

835New energy vehicle motor testing requires both a chiller and a heater, as motor testing covers a wide range of temperature conditions to ensure the performance and stability of the motor under different operating conditions. Chiller: In ...

세부 정보 보기 -

반도체 패키징 및 테스트 분류 기계에 냉각기를 사용해야 하는 이유는 무엇일까요?

1260In the semiconductor packaging testing process, especially in the temperature control process of the sorting machine (test probe station), the use of chillers is mainly based on the following reasons: Temperature stability and accuracy...

세부 정보 보기 -

원자로의 자동 온도 제어 시스템 고장을 해결하는 방법은 무엇입니까?

1220원자로의 자동 온도 제어 시스템의 성능은 매우 중요합니다. 시작할 수없는 고장이 발생하면 가능한 한 빨리 해결해야하며, 그렇지 않으면 제어 할 수없는 온도가 원자로에 영향을 미칩니다.

세부 정보 보기

LNEYA 산업용 냉각기 제조업체 공급 업체

LNEYA 산업용 냉각기 제조업체 공급 업체