다단계 냉동 시스템 원심 컴프레서 수리 지침

After the centrifugal compressor of the cascade refrigeration system is disassembled, the dimensions of each journal (cooperating with the impeller, bearing, coupling, etc.) are measured with an outer diameter micrometer to calculate the roundness and cylindricity deviation. The value should be Within the allowable range. When the tolerance is large, check if the straightness deviation of the spindle is too large. Place the spindle in the casing or place it on the top of the lathe so that the spindle is in a free state. Use a dial gauge to measure the radial runout of the spindle journal.

The centrifugal compressor of the cascade refrigeration system is divided into 4-8 equal parts, and the rotor is driven according to the direction of rotation of the rotor. The large value of the dial gauge swing is the radial circle runout value. At the same time, the straightness deviation of the main shaft is measured at the appropriate position of the main shaft with two dial gauges, and the radial runout value should be no more than 0.01mm. If the over-standard is too large, the main shaft should be replaced.

Check the surface of the journal of the centrifugal compressor of the cascade refrigeration system for scratches, grooves, scratches, grinding points, etc. If necessary, perform flaw detection. Small defects can be scraped and polished by hand; large defects It can be repaired by surfacing, electroplating, spraying, etc., and then ground and polished. When the flaw detection reveals cracks or serious defects, it is generally not repaired and replaced.

At the same time, the end face runout of the centrifugal compressor impeller of the cascade refrigeration system should be measured, and the value should be within the allowable range. If the value of the end face jump exceeds the allowable range value, when the over-standard is small, the repair is generally not performed. When the value is large, the assembly relationship between the impeller and the main shaft can be adjusted by the method of adding the gasket. The impeller should be dynamically balanced and statically balanced after the overhaul. test.

The parts and fittings of the centrifugal compressor of the cascade refrigeration system have the specified technical standards and requirements for use. In the absence of reliable basis, it is necessary to strictly abide by these standards and never lower the standard.

The cascade refrigeration system should have a fixed maintenance and repair plan, carefully learn the correct understanding and use of equipment requirements by the user, and timely cooperate with the on-site user for regular maintenance.

관련 권장 사항

-

초저온 냉장고의 유지 관리 및 유지 보수

1295초저온 냉장고의 유지 관리 및 유지 보수는 정상적인 사용과 수명 연장을 위해 매우 중요합니다. 부정확 한 온도 제어로 인해 보호 대상물이 손상되는 경우가 종종 발생하면 크게 ...

세부 정보 보기 -

You Know What Technical Problems You Need to Know before You Buy A Low Temperature Chamber

980Question 1: Is the temperature change rate of temperature impact test the faster the better? Explanation: Is the temperature change rate faster and better in the temperature impact test? Does the temperature change rate have any effect on the tes...

세부 정보 보기 -

Solution to High and Low Pressure Fault of Water Cooled Chiller

1229The method to eliminate the shortcomings of high and low pressure of water-cooled chiller has always been a key point and difficulty in the industry, so it is very important to master the solutions to the shortcomings of high and low pressure of w...

세부 정보 보기 -

How to install -60°C cryogenic chiller manufacturers equipment

1258-60℃ cryogenic chillermanufacturers are used in the refrigeration and chemical industry, so whatissues should be paid attention to during installation? LNEYA professionalmanufacturers tell you that you should install according to the instructio...

세부 정보 보기

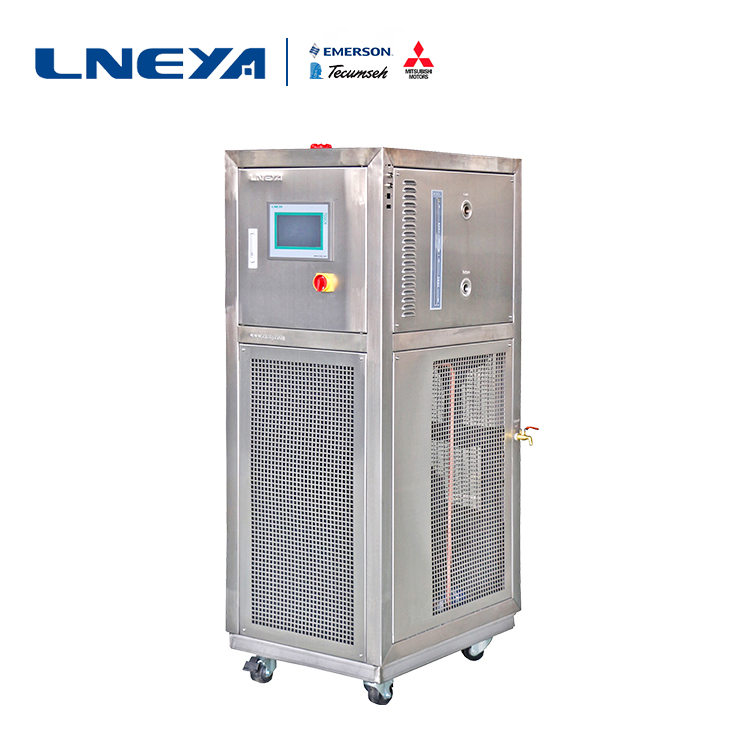

LNEYA 산업용 냉각기 제조업체 공급 업체

LNEYA 산업용 냉각기 제조업체 공급 업체