배터리 테스트 온도 시뮬레이션 시스템이 전기/하이브리드 차량 냉각 테스트에 미치는 영향

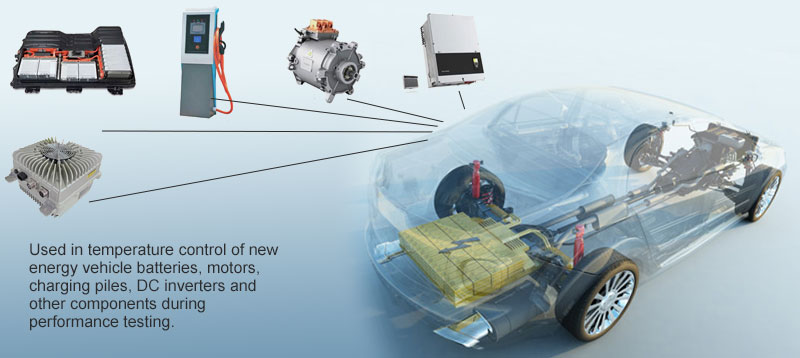

In the electric vehicle industry, batteries are an important part of automobiles, and their performance directly affects the performance of hybrid/electric vehicles. For this reason, relevant manufacturers in the market have launched a battery cooling system test temperature simulation system to efficiently perform battery module charge and discharge tests.

Due to the limited space of the vehicle, the accumulation of heat generated during the operation of the battery will cause uneven temperature everywhere and affect the consistency of the battery cells. Thereby reducing the battery charge and discharge cycle efficiency, affecting the power and energy of the battery, in severe cases, it will also lead to thermal runaway, affecting system safety and reliability. In order to make the battery pack play better performance and life, the battery needs to be thermally managed to control the temperature of the battery pack within a reasonable range.

The battery thermal management system is one of the key technologies to deal with the battery’s thermal related problems and ensure the performance, safety and life of the power battery. The main functions of the thermal management system include: effective heat dissipation when the battery temperature is high to prevent thermal runaway accidents; preheating when the battery temperature is low, raising the battery temperature, ensuring charging and discharging performance and safety at low temperatures; Reduce the temperature difference within the battery pack, suppress the formation of local hot spots, prevent the battery from decaying too fast at high temperature locations, and reduce the overall life of the battery pack.

The temperature environment in the battery pack (PACK) has a great influence on the reliability, life and performance of the battery cell. Therefore, it is particularly important to maintain the temperature within the PACK within a certain temperature range. Air cooling is a kind of heat dissipation method that uses low temperature air as a medium and uses heat convection to reduce the temperature of the battery. It is divided into natural cooling and forced cooling (using a fan, etc.). Liquid cooling technology uses liquid convection heat exchange to remove the heat generated by the battery and reduce the battery temperature. The liquid medium has a high heat transfer coefficient, a large heat capacity, and a fast cooling rate. It has a significant effect on reducing higher temperatures and improving the consistency of the temperature field of the battery pack. At the same time, the volume of the thermal management system is relatively small. Direct cooling (refrigerant direct cooling) uses the principle of refrigerant (R134a, etc.) to evaporate latent heat, establish an air-conditioning system in the vehicle or battery system, install the evaporator of the air-conditioning system in the battery system, and the refrigerant evaporates in the evaporator And quickly and efficiently remove the heat from the battery system to complete the cooling of the battery system.

The heat-related problems of the battery are the key factors that determine its performance, safety, life and cost. The test cooling cycle system is an essential test equipment for new energy vehicles, battery modules, and battery PACK liquid cooling tests. Testing of motor and its controller. LNEYA battery cooling system test temperature simulation system effectively promotes the development of power battery performance, safety and life.

관련 권장 사항

-

Solution to High and Low Pressure Fault of Water Cooled Chiller

1229The method to eliminate the shortcomings of high and low pressure of water-cooled chiller has always been a key point and difficulty in the industry, so it is very important to master the solutions to the shortcomings of high and low pressure of w...

세부 정보 보기 -

산업용 글리콜 온도 사이클 기계에서 압축기 고장을 수리하는 방법

1193산업용 글리콜 온도 기계는 필요한 공정 조건에서 냉장 및 가열 반응을 수행하며 압축기는 핵심 액세서리로 사용됩니다. 고장이 발생하면 작업자는 요약에주의를 기울여야하며 ...

세부 정보 보기 -

온도 충격 테스트 챔버 고장 성능 설명

1077온도 충격 테스트 챔버는 다양한 주요 산업에서 널리 사용됩니다. 사용자는 구매할 때 온도 충격 테스트 챔버를 오랫동안 사용할 수 있기를 바랍니다. 따라서 온도 충격 테스트 챔버의 각 결함을 이해할 필요가 있습니다. .

세부 정보 보기 -

The reason why the semiconductor small thermostat is blocked by refrigeration

1265The small semiconductor small-scale thermostat ice jam is mainly caused by the excessive moisture contained in the refrigeration system. With the continuous circulation of the refrigerant, the moisture in the refrigeration system gradually collect...

세부 정보 보기

LNEYA 산업용 냉각기 제조업체 공급 업체

LNEYA 산업용 냉각기 제조업체 공급 업체