원자로 온도 제어 시스템의 기능은 무엇인가요?

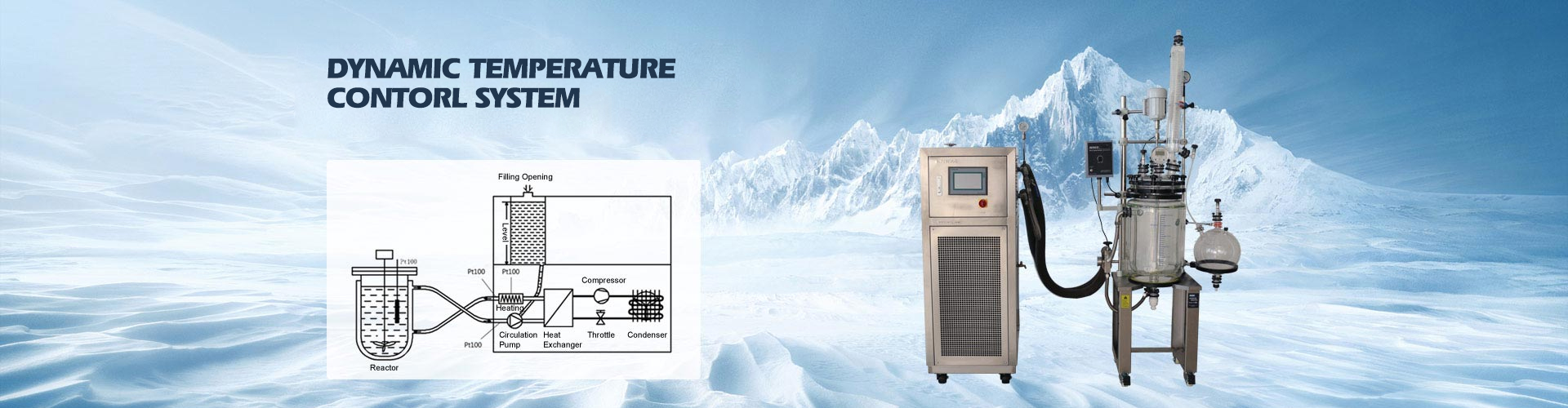

The reactor temperature control system is equipped with various reactors for high and low temperature reflection of liquid and solid. The temperature control system of LNEYA reactor adopts fully closed circulation pipeline, which is efficient in operation and less polluted. So, what are the advantages of the reactor temperature control system?

LNEYA applies the technology to the reactor temperature control equipment, which can dynamically display the operating status of each equipment in real time, including real-time data changes of raw material tank weight, feed rate of various materials, valve operation on the equipment and corresponding temperature. The data display, etc., can simulate the flow chart shape, and the image is intuitive and easy to read.

The reactor temperature control system can display the real-time curve and historical data curve of each process parameter, and compare with the set process curve to guide the production process. The displayed historical curve can be saved for more than one year, which is convenient for users to view at any time. With the various process curves and ratios of the memory in the system, it is possible to issue control requirements to the PLC at any time according to the requirements of the production process, so that the production variety and the rapid change of the production process can be completed.

In addition, the reactor temperature control system can print a variety of production and statistical reports, with a very strong management function, the actual weight of each batch and the corresponding temperature, pressure data, etc., to print the data cost Accounting. The LNEYA autoclave automatic control system can perform manual and automatic interference-free switching operations. In order to enhance the performance of the whole system without losing flexibility, the system is equipped with computer operation and can be operated by touch screen, whether manual or not. Automatic or console button operation can be implemented very conveniently.

The reactor temperature control system uses an intelligent control technology to dynamically adjust the temperature by automatically adjusting the multi-parameters of the reactor jacket cooling water and material feed rate, thus allowing various physical processes and The chemical reaction process is more efficiently controlled.

The LNEYA reactor temperature control system uses a complete safety protection device to ensure safety problems in the production process of the reactor temperature control system to a greater extent.

(This article source network, if there is infringement, please contact LNEYA to delete, thank you.)

관련 권장 사항

-

High and low temperature alternating wet heat shock test box function description

953Consumers need to pay attention to the performance of the high and low temperature alternating wet heat shock test chamber. LNEYA's test chamber is closer to the needs of the purchasing company. The high and low temperature alternating heat and hu...

세부 정보 보기 -

선형 급격한 온도 변화 테스터 비우기 및 채우기 지침

1200선형 급격한 온도 변화 테스터를 시작하기 전에 화재 방지, 보호, 누출 방지 및 기타 도구와 같은 관련 보호 조치가 마련되어 있는지 확인하십시오. 전원 공급 장치가 제자리에 있는지 확인 ...

세부 정보 보기 -

김이 나는 시스템 온도 제어 안전 요구 사항

1186김이 나는 시스템 온도 제어는 우시 구아냐 엘네야에서 설계하고 생산한 저온 냉장고 중 하나입니다. 온도 범위는 -5°C에서 -150°C입니다. 2 차 과냉각 기술이 채택되고 냉동은 ...

세부 정보 보기 -

Temperature control and chillers in oxidation diffusion process

774The oxidation diffusion process is a key step in semiconductor manufacturing. It is mainly used to form precise oxide layers and doping, and has extremely strict requirements for temperature control. In this process, the chiller, as an imp...

세부 정보 보기

LNEYA 산업용 냉각기 제조업체 공급 업체

LNEYA 산업용 냉각기 제조업체 공급 업체