The significance of temperature in IC testing

Every integrated circuit (IC) goes through two type of tests before it can be sold and used to build a product: the first is called a wafer test; the second is called final test.

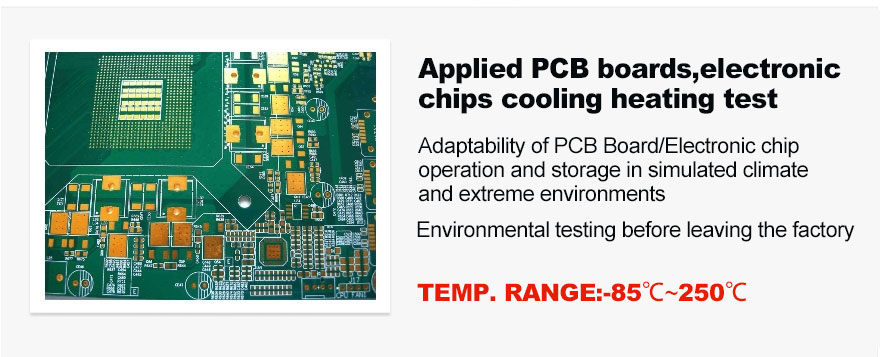

With the improvement of integrated circuit electrical test technology and requirements, some chip products have integrated temperature sensors, or through the voltage changes of some precision diodes linearly related to temperature changes, the current actual chip under test is calculated through a series of formulas temperature.

This means that if the temperature does not meet the standard, it will also be regarded as a defective product, which will also affect the yield of the final test, and due to the inaccuracy of the temperature, it will also cause some electrical test failures. Therefore, the temperature control problem in the final test of the semiconductor is beginning to be taken seriously.

Under normal circumstances, the low temperature test is -40 ℃, the upper and lower limits of the test program temperature test items are controlled at +/- 10 ℃, and more strictly +/- 5 ℃. In the manufacturing of semiconductors electronic components for harsh environments, the IC package assembly and test stages of engineering and production include burn-in, electronic hot and cold testing at temperature, and other environmental test simulations. These semiconductor devices and electronics, once put in real world applications, can get exposed to extreme environmental conditions.

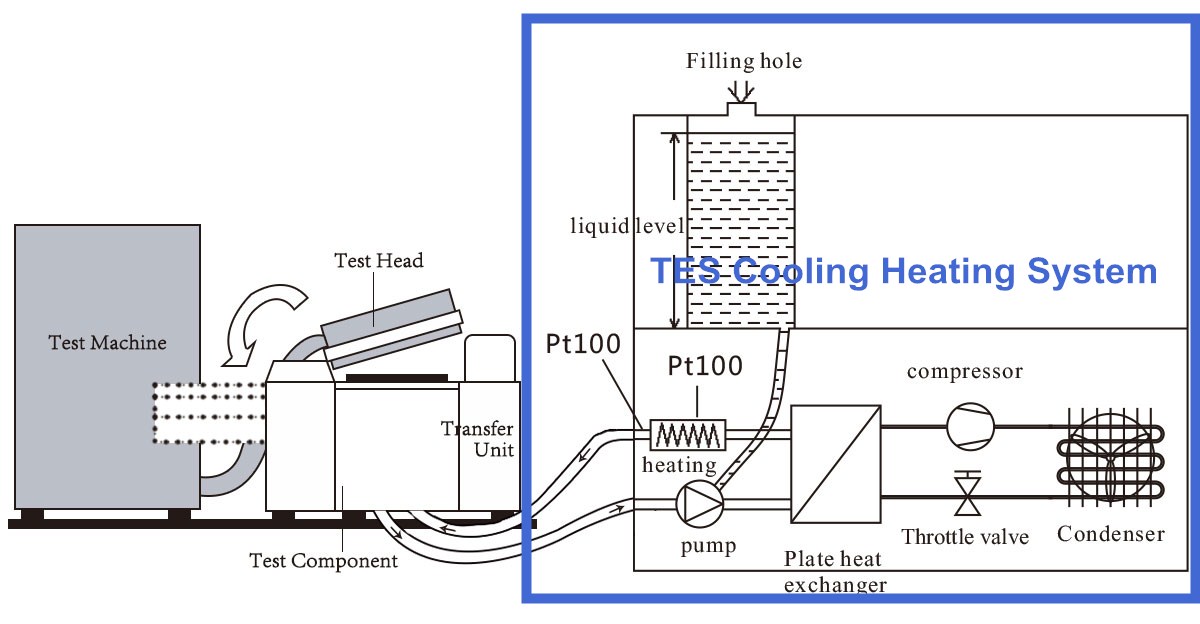

The LNEYA TES-85 has a temperature range from -80 ° C to + 225 ° C without the use of LN2 or CO2. Just connect the pipeline to the test area of the IC and other test benches, This lets you easily temperature test your electronic semiconductor IC devices.

Precision Temperature Forcing Systems use a direct temperature-controlled stream of hot or cold air to provide a precise thermal environment for temperature testing, conditioning and cycling of electronic and non-electronic assemblies and sub-systems. The ThermalAir Temperature System enables the test. This allows you to perform temperature simulation tests in situ, at a specific location, at your tester station, test bench or directly on the unit under test.

Bring temperature to your test for Semiconductor IC devices and other semiconductor packages. LNEYA TES series equipment temperature control range: -85 ° C ~ 200 ° C; power range: 2.5kW ~ 25kW; temperature control accuracy: ± 0.3 ° C. The pressure of the refrigeration system is realized by a pressure gauge (high pressure, low pressure); the pressure of the circulation system is detected by the pressure sensor and displayed on the touch operation screen. Refrigerant uses R404A R23 / R14 mixed refrigerant environmentally friendly refrigerant.

관련 권장 사항

-

Heating and cooling system for chemical reaction kettle reaction process

1225In the process of chemical chemical reaction, material temperature is an important production process parameter. For example, in salt crystallization, solution separation, organic pigment and intermediate processing, temperature control is particu...

세부 정보 보기 -

유리 반응기에 대한 냉각 및 가열 시스템의 영향

1241유리 반응기는 부피가 작고 구조가 명확하며 유연한 방식으로 직렬 및 병렬로 편리하게 작동하여 다양한 공정 상황을 완벽하게 충족시킬 수 있으며 반응 경로에 금속 접촉이 없으며 인라인 ...

세부 정보 보기 -

방폭형 워터 칠러가 필요한 곳은 어디인가요?

900방폭형 냉동 장치 냉각기(방폭형 냉각기)는 주로 폭발 위험이 있는 환경에서 냉각 공정의 안전과 신뢰성을 보장하기 위해 사용됩니다. 이 유형의 장비는 특별히 설계되었습니다 ...

세부 정보 보기 -

우시 관야: 새로운 에너지 개발을 위해 냉동 난방 장비의 R&D에 집중하다

1425On October 17, 2018, the three-day API was held in Nanjing International Expo Center. The exhibition was crowded with people. Wuxi Guanya was a frequent visitor to the API. Wuxi Guanya Constant Temperature Refrigeration Technology Co., Ltd. (herei...

세부 정보 보기

LNEYA 산업용 냉각기 제조업체 공급 업체

LNEYA 산업용 냉각기 제조업체 공급 업체