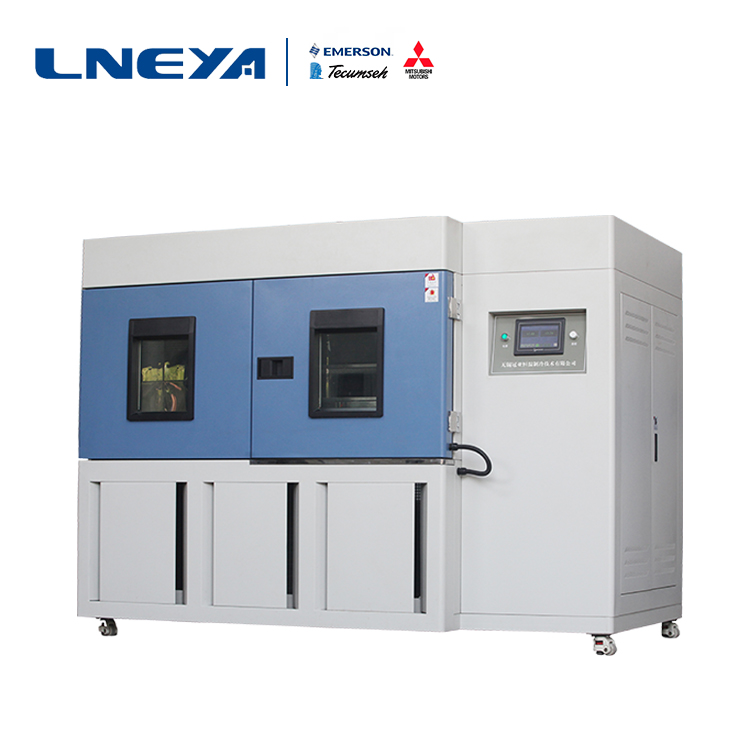

Small high and low temperature impact test chamber volume selection instructions

When the test product (components, components, components or complete machine) is placed in a small high and low temperature impact test chamber for testing, in order to ensure that the atmosphere around the test product can meet the environmental test conditions specified in the test specification, the small high and low temperature impact test There should be some points of attention between the working size of the box and the outer dimensions of the tested product. The volume of the tested product should not exceed (20~35)% of the effective working space of the test box. It is recommended to use no more than 10% for products that generate heat during the test. The ratio of the windward cross-sectional area of the test product to the total area of the test chamber on the section is not more than (35 to 50)%. The distance of the outer surface of the test product from the wall of the test chamber is at least 100 to 150 mm.

After the test piece is placed in the box, the smooth passage is occupied, and the narrowing of the passage will result in an increase in the flow rate of the air flow. Accelerate the heat exchange between the gas stream and the test piece. This is inconsistent with the reproduction of environmental conditions, because in the relevant standards, the temperature flow around the test specimens in the test chamber should not exceed 1.7 m/s, so as to prevent the test specimens and the surrounding atmosphere from being produced. Heat transfer. If the volume of the test piece or the wind-breaking area is increased without restriction in the test, the airflow speed will increase beyond the wind speed specified in the test standard during the actual test, and the validity of the test results will be suspected.

The accuracy index of the environmental parameters in the working chamber of the small high and low temperature impact test chamber is the result of the test under no-load condition. Once the test piece is placed, the uniformity of the environmental parameters in the working chamber of the test box will be affected. The greater the space occupied, the more serious this effect will be.

According to the principle of heat conduction, the temperature of the gas flow near the tank wall is usually 2 to 3 °C from the center temperature of the flow field, and may reach 5 °C at the upper and lower limits of the high and low temperature. The temperature of the tank wall is different from the temperature of the flow field near the tank wall by 2~3 °C (depending on the structure and material of the tank wall). The greater the difference between the test temperature and the external atmospheric environment, the greater the above temperature difference, therefore, the distance from the tank wall The space within the distance (100 to 150 mm) is an unusable space.

The volume selection instructions above the small high and low temperature impact test chamber do not know that you understand it. I believe that users can better select the equipment after reading these.

관련 권장 사항

-

Single cone dryer cooling and heating devices

812Single cone dryer is a commonly used solid material drying equipment, widely used in chemical, pharmaceutical, food and other industries. In order to ensure temperature control during the drying process, it is usually necessary to equip ...

세부 정보 보기 -

일반적으로 사용되는 냉각기의 분류 및 장단점

1147냉각기의 분류와 장단점은 무엇일까요? 오늘 함께 살펴보겠습니다. 1. 칠러의 다양한 분류 방법1. 응축기 냉각 방식에 따라 : 수냉식 냉각기 및 그룹 공냉식 수냉식 냉각기 ...

세부 정보 보기 -

에틸렌 글리콜 냉동 장치가 강력한 공격으로 12 년 만에 LNEYA 브랜드를 만들었습니다.

1376성능 향상 위치 냉각 및 가열 반응을 수행할 때 많은 경우 냉매가 자체적으로 냉각 대상 물체를 냉각할 수 없습니다. 따라서 냉동 시스템을 냉각하기 위해 냉각수(또는 냉매)가 필요합니다.

세부 정보 보기 -

Instructions for Manufacturers of Cold Plate Freezer [-5 to -150 Degrees of Refrigeration]

1136There are various manufacturers of Low Temperature low temperature cold plate freezer. It is widely used in glass reactor, metal reactor and bioreactor to control temperature and temperature.Using Range of Low Temperature Cold Plate FreezerMediu...

세부 정보 보기

LNEYA 산업용 냉각기 제조업체 공급 업체

LNEYA 산업용 냉각기 제조업체 공급 업체