Why is there air in the reactor temperature control system?

The impurity gas in the reactor temperature control system is to increase the condensing pressure of the refrigeration system, thereby increasing the condensing temperature, increasing the exhaust temperature of the compressor, increasing the power consumption, reducing the cooling efficiency, and possibly the exhaust gas temperature is too high. The carbonization of the lubricating oil affects the lubrication effect, and in severe cases, the refrigeration compressor motor is burnt.

The gas generated in the reactor temperature control system may be leaking air. It may be when the refrigerant is filled or lubricated, the outside air is taken into the air, or the temperature of the reactor temperature control system is not tight enough to cause air to enter. Inside the system. In addition, gas is generated due to decomposition of the refrigerant oil, impure refrigerant, and corrosion of the metal material. Of course, Wuxi Guanya uses a fully enclosed circulation system on the reactor temperature control system to prevent this air from entering the reactor temperature control system.

In general, the gas in the reactor temperature control system is expressed in the reactor temperature control system compressor exhaust pressure and exhaust gas temperature rise, the pressure gauge pointer on the condenser (or reservoir) violently swings, the compressor The cylinder hair is hot, the condenser shell is very hot; the surface temperature of the evaporator temperature control system is unevenly frosted. When there is a large amount of gas in the reactor temperature control system, the ambient temperature cannot be lowered due to the decrease of the cooling capacity of the reactor. The machine runs for a long time, and even the high-pressure relay operates to stop the compressor.

If the reactor temperature control system has these gases, the pressure of the refrigeration system can be measured by a pressure gauge to compare with the saturation pressure at that ambient temperature. If the measured pressure is greater than the saturation pressure at ambient temperature, the system contains gas.

If the above-mentioned gases are found in the reactor temperature control system, it is necessary to eliminate these gases in time and solve the faults in time.

관련 권장 사항

-

반도체 제조 공정 중 멀티채널 냉각기가 필요한 공정은 무엇입니까? 왜 필요한가요?

1022화학 기상 증착(CVD): CVD 공정에서는 다중 채널 냉각기를 사용하여 반응 챔버 벽, 열교환기 및 가스 예열 교환기를 냉각하여 안정적인 반응 챔버 온도를 유지하여 정밀한 제어를 보장합니다.

세부 정보 보기 -

반도체 온도 테스트 시스템 적용 범위 설명

1530The semiconductor temperature test system is LNEYA's new device for semiconductor chip testing. So what range does the semiconductor temperature test system apply? Users need to understand the specific application range to select the appropriate s...

세부 정보 보기 -

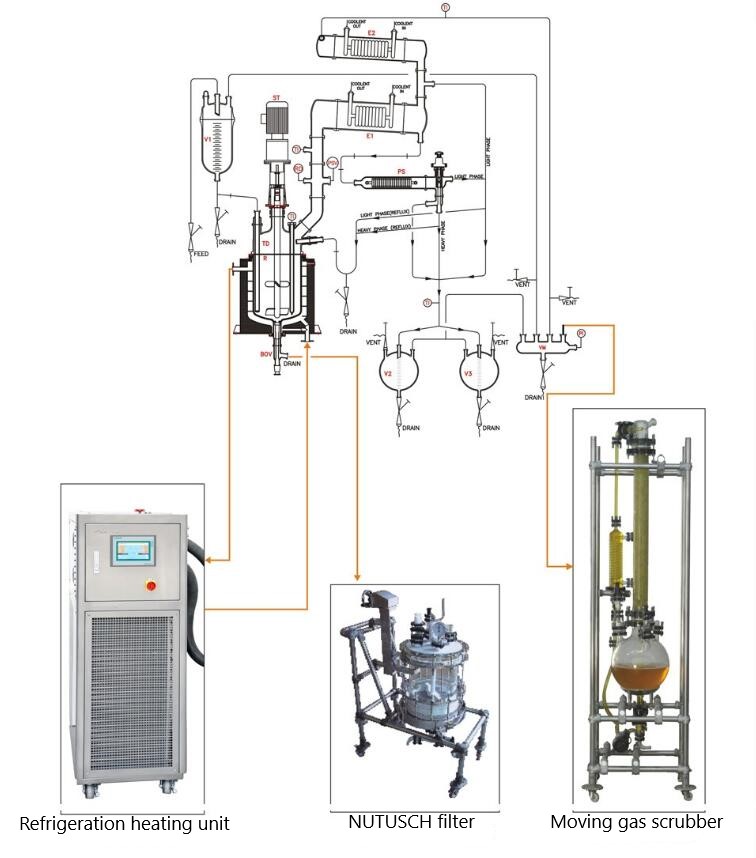

500L 반응기 분산형 온도 제어 장치 시스템

839500L 반응기는 산업 제조 및 제약 회사에서 비교적 큰 용량의 반응 용기입니다. 일반적으로 파일럿 규모 또는 중소 규모 생산 단계에서 사용되며 여러 산업 분야에 널리 사용됩니다....

세부 정보 보기 -

유기 폐가스 정화 응축 셧다운 참고 사항

1238유기성 폐가스를 정화 및 응축하는 경우 작동 중에 고장이 발생하면 가동을 중단하고 제때 폐기해야 합니다. 그렇다면 유기성 폐가스 정화 및 응축이 종료된 후에는 어떻게 사용할 수 있을까요?

세부 정보 보기

LNEYA 산업용 냉각기 제조업체 공급 업체

LNEYA 산업용 냉각기 제조업체 공급 업체