Advantages of Industrial Chillers in Refrigeration

In recent years, the manufacturing industry

has entered a golden age. The market competition is fierce, and the

requirements for product quality have been greatly improved. In fact, in the

process of improving product quality, manufacturers often ignore a subtle and

important factor. In the production process, due to the continuous heat

generated by machinery, molds and industrial reactions, when the temperature

exceeds the degree that the material can bear, the product quality is unstable.

Taking the production of plastic products and electroplating as an example, the

cooling time in the production of plastic products accounts for more than 80%

of the whole cycle. Therefore, it is particularly important to reduce the

cooling time. The cooling water can absorb heat in time, which can rapidly

reduce the temperature in the mold cavity and accelerate the finalization of

the product. In the electroplating industry, cooling water can reduce the

temperature of electroplating solution and keep the temperature within a

certain range, so that metal molecules can quickly attach to the surface of

plated parts with stable current, so as to make the product smooth and increase

the density.

Industrial water chiller is the most common

and advanced refrigeration equipment in modern times. Water chiller is an

important auxiliary unit for industrial development. Nowadays, there are more

and more industrial chiller manufacturers. Users should make the best choice

according to their actual working conditions.

Industrial water chillers are commonly

known as industrial water machines, industrial coolers, industrial ice machines,

etc. Although the product parameters of each industrial chiller manufacturer

are different, chillers are still widely used in all walks of life, and there are

countless names. Its working principle is a multifunctional temperature control

machine, which removes liquid vapor through compression or heat absorption

refrigeration cycle. The steam compression industrial chiller consists of four

main components: steam compression refrigeration cycle compressor, evaporator,

condenser and some metering devices, so as to realize different refrigerants.

관련 권장 사항

-

신에너지 차량의 배터리 냉각 시스템을 청소하는 방법은 무엇인가요?

917새로운 에너지 모델의 배터리 냉각 시스템은 먼저 습식 커튼 상단의 나사 3 개를 풀고 습식 커튼 상단의 루버를 잡고 습식 커튼을 바깥쪽으로 부드럽게 당긴 다음 약간 들어 올려서 ...

세부 정보 보기 -

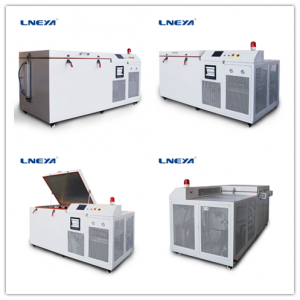

Instructions to Use Industrial Cryogenic Refrigerator

1234Industrial refrigerators are one of the cold water machines. It is classified according to the cooling mode of the cold water machine itself. It is divided into air cooling type refrigerators and water cooled refrigerators. Structural features: a ...

세부 정보 보기 -

Points for Attention in the Use of Recirculating Chillers for Distillation Equipment

1169The recirculating chiller is a supportingdistillation equipment, which separates different mixtures by vaporizing andcondensing multiple times. It can be used well with the distillation equipment,which can not only improve its operating efficie...

세부 정보 보기 -

새로운 에너지 모터 테스트 수냉 시스템의 고장률을 줄이는 방법은 무엇입니까?

1031새로운 에너지 모터 테스트 수냉 시스템은 사용 중 사용에주의를 기울여야하며, 아무리 좋은 장비를 오랫동안 사용하더라도 일부 문제가 다소 발생할 수 있습니다. 그렇다면 사용 중 장비의 고장률을 최소화하려면 어떻게해야할까요?...

세부 정보 보기

LNEYA 산업용 냉각기 제조업체 공급 업체

LNEYA 산업용 냉각기 제조업체 공급 업체