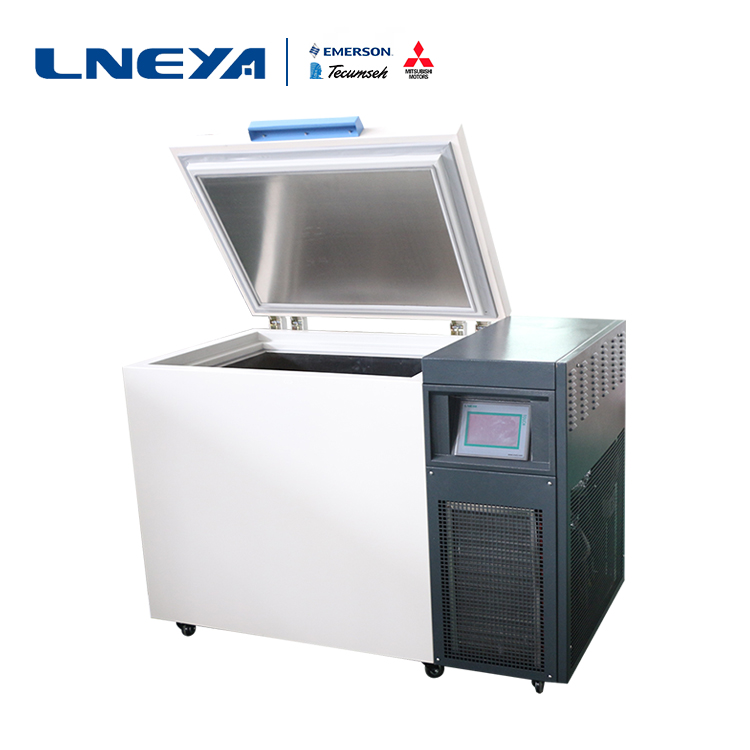

Environmental description of large industrial freezer condenser

In industrial cold processing, large industrial freezers are one of the more used equipment. Among them, the condenser is one of the main components, and its performance is very important. Therefore, when choosing, everyone still needs to understand.

When the large industrial freezer system is in operation, the reason for the change of the condensing temperature is the change of the temperature of the cooling medium. The temperature of the condensing depends on the heat transfer area of the condenser, the temperature of the cooling medium, the purity and sufficient amount of the refrigerant, and the compressor. Exhaust temperature and displacement, etc. In normal operation, the condensing temperature and pressure are basically stable, and the space can be adjusted. It is often caused by a system failure (such as sudden water cut or improper number of condensers), causing the machine to malfunction. In operation, it should be checked frequently and found. When you have a problem, you should find the cause and solve it in time to avoid the more serious the damage to the machine.

The temperature environment of different types of condensers for large industrial freezers is different. The condensation temperature of vertical, horizontal shell and shower condensers is 4-6 °C higher than that of cooling water, and the condensation of evaporative condensers The temperature is 5 to 10 ° C higher than the wet bulb temperature of the outdoor air in summer, and the temperature of the air-cooled condenser is 8 to 12 ° C higher than the air temperature.

In Wuxi Guanya LNEYA large industrial freezer refrigeration system, the external heat release of the refrigerant is the normal operation of the condenser. After the high temperature gas discharged from the compressor enters the condenser, the heat is transferred to the medium (water or air), the refrigerant. The steam is cooled and condensed into a liquid, and the liquefied refrigerant enters the evaporator through throttling, thereby achieving the purpose of repeated cycle refrigeration of the industrial explosion-proof large-scale industrial refrigerator. If the accumulator and the condenser are installed in the large industrial freezer at the same height, the outlet pipe at the bottom of the condenser needs to be bent upward to the upper part of the accumulator. This may cause the liquid seal to appear in the pipe. The exhaust function of the compressor, once there is a certain liquid level in the reservoir, will reduce the condensation area of the condenser, increase the condensation temperature and pressure, increase the power consumption, and cause the operating conditions of the freezer refrigeration system to be poor.

The condenser and the accumulator in the large industrial freezer are one of the most important accessories. The above accessories knowledge hopes that everyone can understand clearly.

관련 권장 사항

-

냉각판 냉동고의 적용

1056냉판 냉동고의 냉동 시스템은 급속 냉동 및 낮은 제한 온도를 가진 2 차 과냉각기 기술을 채택합니다. 그것은 수입 브랜드 이름 반밀폐 피스톤 압축기, 반밀폐 피스톤 복합 압축을 사용합니다 ...

세부 정보 보기 -

최소 40도 냉장고 사용 시 주의사항

117140도 이하 냉장고의 온도는 실내 온도입니다: 5-32 °C, 상대 습도 80%/22 °C, 지상과의 거리> 10cm, 고도 2000m 이하, 안전한 환경은 낮은 40 도의 원활한 작동을 보장합니다 ...

세부 정보 보기 -

Cooling and heating temperature control equipment for liquid distribution system

921The cooling and heating temperature control equipment of the liquid distribution system is a dynamic temperature control system produced by LNEYA. When we purchase the cooling and heating temperature control system of the liquid distribution s...

세부 정보 보기 -

The Importance of Choosing a Quality Chiller Manufacturer

798The first is professional operators.Professional refrigeration practitioners are the prerequisite for the maintenance, repair and maintenance of the chiller. If there are no professionals to work on the refrigeration equipment, it will not only c...

세부 정보 보기

LNEYA 산업용 냉각기 제조업체 공급 업체

LNEYA 산업용 냉각기 제조업체 공급 업체