What reactions are microchannel reactors suitable for?

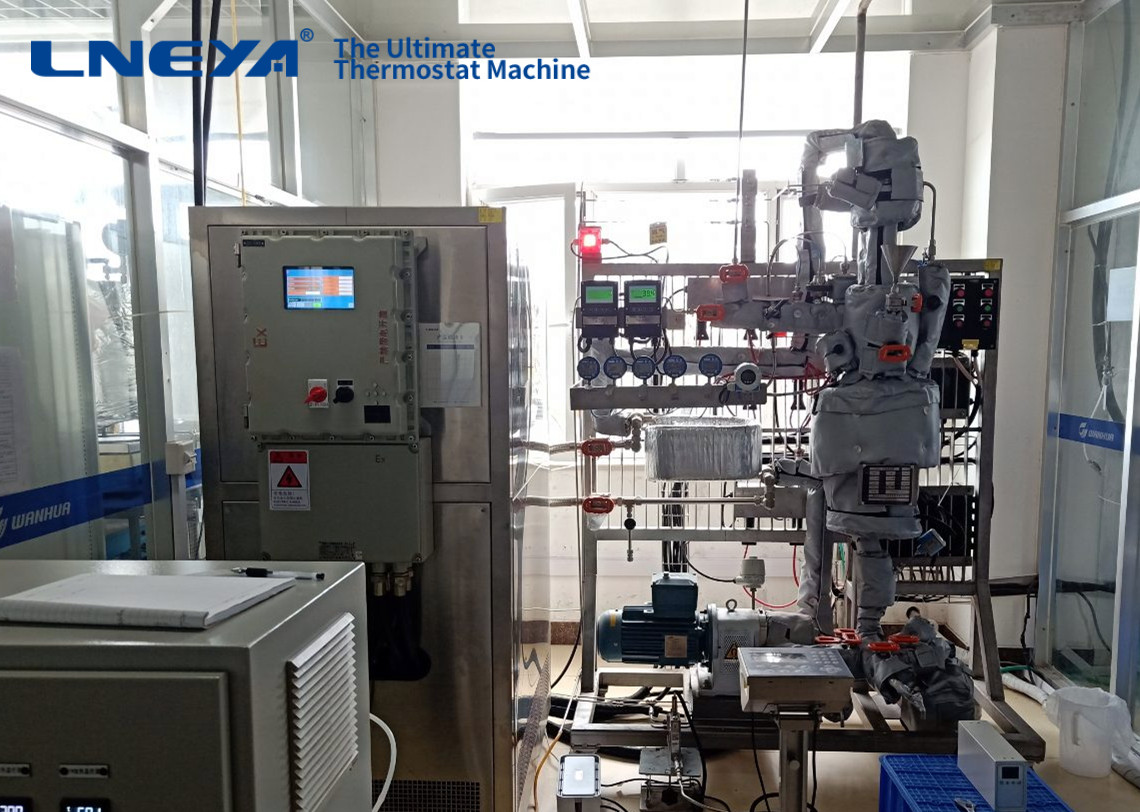

In recent years, micro-chemical technology has developed rapidly, and micro-channel reactors have attracted more and more attention. Microchannel reactors are manufactured with the help of special micromachining technology. They have the advantages of high mass transfer efficiency, good heat transfer efficiency, precise automatic control, small reaction volume and small amplification effect.

In the production process using p-cresol as raw material, a certain concentration of dilute nitric acid is generally added to the traditional kettle type reaction kettle, and the temperature of the reaction kettle is controlled at a low temperature, and then p-cresol is added dropwise at a certain speed. The temperature gradually increased, and the reaction was complete in about 2-3 hours. In the traditional reaction kettle, the reaction time is long, and as the reaction proceeds, the temperature is prone to side reactions, which reduces the yield of the product and makes subsequent separation and purification operations difficult.

In terms of structural characteristics, the current microchannel reactor can be used for the following types of reactions: widely used in various high-risk chemical reactor processes, used in liquid-liquid, gas-liquid, solid-liquid, and solid-liquid oxidation in the reaction. Reaction, nitration reaction, diazotization reaction, precipitation extraction application, phosgenation reaction, sulfonation reaction, ammoniation reaction, chlorination reaction, etc. Solve most of the difficulties and pain points of chemical reactors, metal material microchannel reactor, material selection: 316L stainless steel, 904 stainless steel, Hc, titanium, zirconium and tantalum materials, and design microchannel reactions with different structures for different reaction types device. The channel size of the microchannel reactor itself is very small, and it is easy to be blocked. Most of the reactors containing heterogeneous catalysts are not suitable for the use of microchannel reactors. In addition, the reaction system that is easy to generate larger particles is not suitable for the use of microchannel reactors. Corrosion issues cannot be ignored.

The reaction speed of the microchannel reactor itself is fast, but the reaction is violent, strong exothermic, and the product is easily destroyed. , significantly improve the heat exchange efficiency, improve the selectivity of the reaction, reduce the occurrence of side reactions caused by the problem of reaction temperature, and improve the yield of the product.

관련 권장 사항

-

초저온 냉동 제조업체, 냉동 시스템 막힘 원인 분석

1340With the continuous development of technology, ultra-low temperature refrigeration technology is also constantly developing, and manufacturers are also increasing. Of course, the technology of different manufacturers is different. Once the refrige...

세부 정보 보기 -

Vocs condensation adsorption technology energy control instructions

1322The vocs condensation adsorption technology has been developed under the current trend of environmental protection. The LNEYA vocs condensation adsorption technology uses condensation adsorption technology. In order to save operating costs, it is ...

세부 정보 보기 -

Cooling method for semiconductor testing chiller to meet temperature control requirements

1327The biopharmaceutical field requires high-precision temperature to control the activity of enzymes and the production of products; the chemical industry field requires specific temperatures to stabilize chemical reactions; the electronic manufact...

세부 정보 보기 -

산업용 냉각기 시스템 선택 방법

1150산업용 냉각기 시스템을 구매하고 싶으신가요? 신뢰할 수 있는 산업용 워터 칠러 시스템을 구매하고 싶으신가요? 고품질 산업용 냉각기 시스템을 구입하고 싶으십니까? 구매 방법?1. 공정 요구 사항 장비에 관계없이 LNEYA는 사용자에게 위트 ...

세부 정보 보기

LNEYA 산업용 냉각기 제조업체 공급 업체

LNEYA 산업용 냉각기 제조업체 공급 업체