화학 및 제약 반응기에서 온도 제어 시스템 TCU의 역할

The temperature control of the reaction kettle in drug research and development and chemical experiments, as well as the temperature control in small-scale experimental production and industrial production processes, require highly dynamic temperature control systems. When controlling the temperature of the reaction kettle, it is necessary to quickly and efficiently compensate for the absorption and exotherm of the chemical reaction.

Many reactors mix or chemically react materials, often accompanied by exothermic or endothermic processes. This part of heat needs to be balanced by a device to maintain a certain temperature range to ensure normal production. ,

Reactor temperature control requires different heating and cooling rates according to different reaction material characteristics. The working environment of some reactors has special requirements, which affects temperature control. How to accurately control the temperature of the reactor needs to be on site Understand the process conditions, such as explosion-proof treatment, or the control part is separated from the mechanical part.

Most temperature control applications involve stainless steel and glass reactors. The stainless steel reaction kettle is more durable, while the glass reaction kettle allows users to observe the reaction process in the kettle body. The reaction kettle generally has an internal cavity, and the materials to be temperature controlled are placed in this cavity. The internal cavity is surrounded by a jacket through which heat transfer oil can pass. The temperature control system is connected to the jacket of the reactor. In order to control the temperature of the reaction kettle, the temperature control system continuously drives the heat transfer oil into the jacket of the reaction kettle through the circulation pump. The sudden temperature change inside the reactor will be compensated by the rapid heating and cooling of the temperature control equipment to achieve dynamic balance. The thermal oil is heated and cooled in the temperature control equipment.

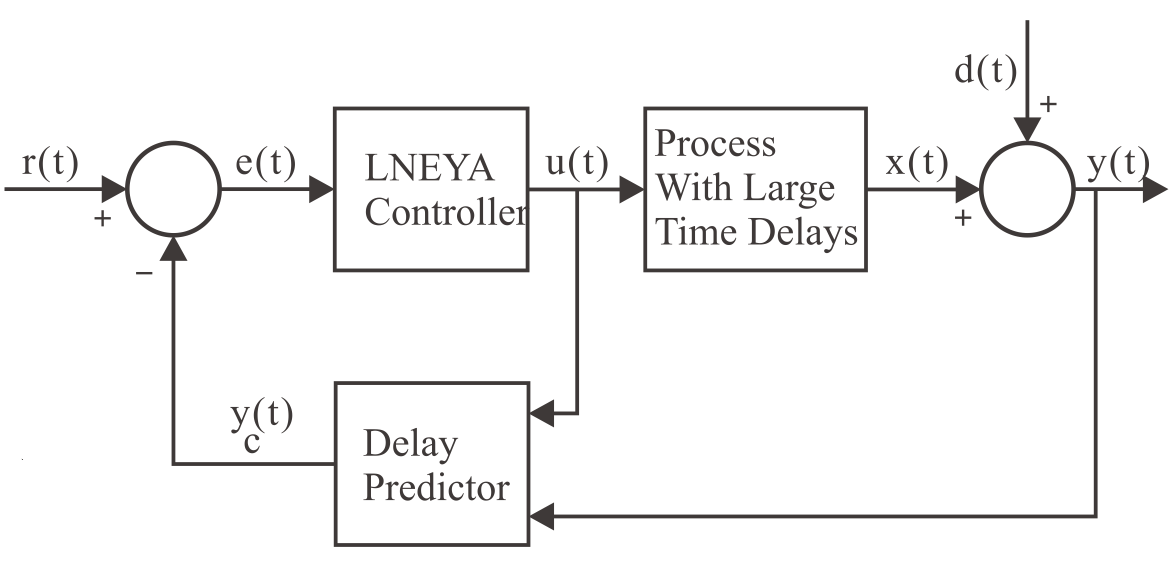

The LNEYA reaction kettle temperature controller TCU uses concentrated heat energy in the kettle to control the temperature of the process, ensuring that only one type of thermally conductive liquid flows into the jacket of the reaction vessel, reducing the problem of thermal reaction delay. Through three-point temperature sampling (material temperature point, temperature control system outlet and inlet temperature), there is no built-in expansion tank, which ensures that the heat absorption and heat release process will not affect the efficiency of the heat transfer oil. Due to the special type of the production workshop, we accept the customization of explosion-proof models, just need to tell us the temperature control effect you want to achieve.

관련 권장 사항

-

How to clean air control system?

1313In order to respond to the requirements of the two types of society in the country, environmental protection and conservation have become increasingly important. Therefore, in order to extend the life of the product, it is still necessary to have ...

세부 정보 보기 -

Introduction to cold plate liquid cooling system products and equipment

1149Introduction to cold plate liquid cooling chiller

세부 정보 보기 -

공랭식 및 수랭식 15P 냉동 장치의 차이점

1243수요 조건이 다르기 때문에 선택한 15P 냉동 장치가 공랭식 및 수냉식 인 경우 차이점은 무엇입니까? 공냉식 15P 냉동 장치에는 본체에 단열 물 탱크와 워터 펌프가 포함되어 있으며, ...

세부 정보 보기 -

Is the low temperature cooling unit – 120 degrees cooling effect reliable?

1188LNEYA specializes in the production of single-fluid cryogenic cooling units, the cooling temperature range is from -150 degrees to -5 degrees, which can meet different cooling temperature requirements. The products are widely used in low temperatu...

세부 정보 보기

LNEYA 산업용 냉각기 제조업체 공급 업체

LNEYA 산업용 냉각기 제조업체 공급 업체