급격한 온도 변화 테스트 챔버 온도 제어 지침

The selection of the humidity range of the rapid temperature change test chamber should be noted that the corresponding temperature range should be indicated after the humidity index or the dew point temperature should be given. Because relative humidity is directly related to temperature, for the same moisture content, the higher the temperature, the lower the relative humidity. To achieve high temperature and high humidity, it is only necessary to spray water vapor or atomized water droplets into the air of the cabinet to humidify. Low temperature and low humidity are relatively difficult to control, because the moisture content at this time is very low, and sometimes it is much lower than the moisture content in the atmosphere, and it is necessary to dehumidify the air flowing in the tank to make the air dry.

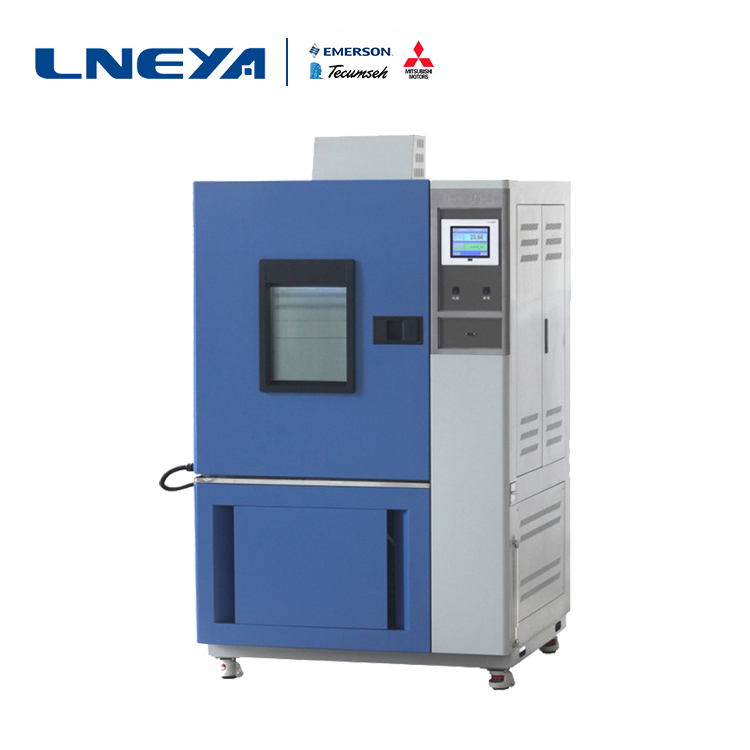

The common rapid temperature change test chamber generally refers to a constant rapid temperature change test chamber, which is controlled by setting a target temperature and the test chamber has the ability to automatically thermostat to the target temperature point. The control method of the constant temperature and humidity test chamber is similar. Set a target temperature and humidity point. The test chamber has the ability to automatically adjust the temperature to the target temperature and humidity point. The high and low temperature alternating test chamber has the program of setting one or more high and low temperature changes and circulations. The test chamber has the ability to complete the test process according to the preset curve, and can control the temperature rise within the range of heating and cooling rate capability. The rate of temperature drop, that is, the temperature rise and temperature drop rate can be controlled according to the slope of the set curve.

Similarly, the high and low temperature alternating heat and humidity test chamber also has a preset temperature and humidity curve, and the ability to control according to presets. Of course, the alternating test chambers all have the function of a constant test chamber, but the manufacturing cost of the alternating test chamber is higher, because the alternating test chamber needs to be equipped with a curve automatic recording device, a program control device, and the test chamber must be solved in the working chamber. When the temperature is high, the refrigerator is turned on. Therefore, the price of the alternating test chamber is generally 20% higher than the price of the constant test chamber. Therefore, we should be realistic and take the test method as the starting point, choose a constant test box or an alternating test chamber.

Different rapid temperature change test chamber manufacturers have different quality, so users need to understand the rapid temperature change test chamber and make more detailed choices.

관련 권장 사항

-

Temperature control of integrated circuit/chip wafer quality and reliability test items

1290The most basic part of making a chip is design-tape-package-test. The chip cost structure is generally 20% of labor cost, 40% of tape, 35% of package, and 5% of test. The test is actually the most in all aspects of the chip. "Cheap" step, but the...

세부 정보 보기 -

초저온 컴프레서 장치에서 필터의 작용에 대한 설명

1142In order to stabilize the operation of the ultra-low temperature compressor unit, the performance of the compressor is very important, and in addition to the compressor, the filter is also important. In order to maintain normal operation, it is ne...

세부 정보 보기 -

The Difinition and Application of Heating Cooling Circulator

1026Before discussing how to choose the right brand of heating cooling circulator, we need to know the definition and application of heating and cooling circulator. Definition: thermostatic waterbath is also called the thermostatic water tank, constan...

세부 정보 보기 -

저온 순환 장치의 프로스팅을 해결하는 방법은 무엇입니까?

1388저온 순환 장치 프로스팅의 고장은 주로 압축기 복귀 공기 온도가 너무 낮기 때문에 스로틀 밸브 액체 냉매 공급이 저온 순환 장치에서 정상 상태 일 수 있습니다 ...

세부 정보 보기

LNEYA 산업용 냉각기 제조업체 공급 업체

LNEYA 산업용 냉각기 제조업체 공급 업체