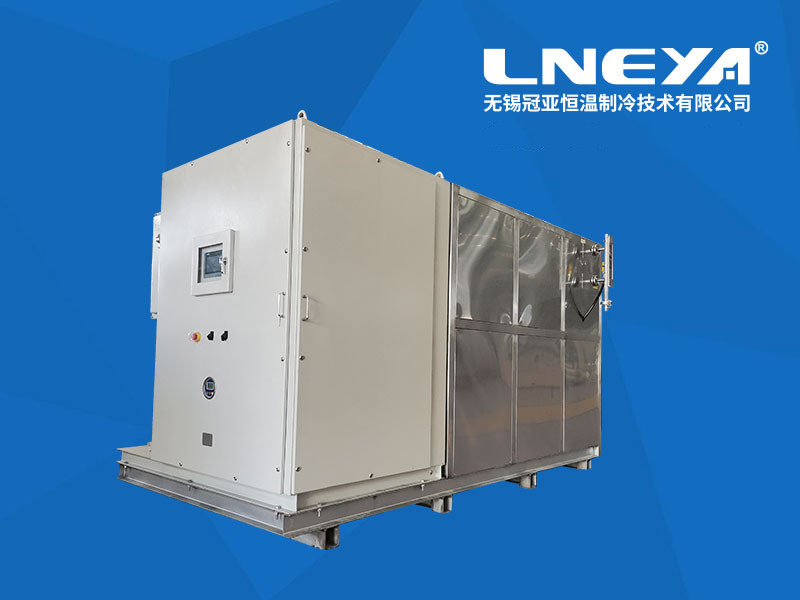

Low temperature refrigeration unit maintenance inspection

Low-temperature refrigeration units usually need to do a maintenance. After the maintenance is done, it is not easy to fail, and there will be more markets. If it is not easy to fail, it will not stop working, which is equivalent to saving the company’s cost. It should be noted that the low-temperature refrigeration unit is maintained. It is very important to lubricate the industrial machinery at ordinary times, because it is always in operation, and the parts that run frequently must be lubricated regularly. If lubrication is not added, the friction will be large. The parts are worn out, so they should be observed and inspected regularly.

Different configurations use different lubricants:

If a problem with the low-temperature refrigeration unit is found, it should be replaced immediately. Different configurations require different lubricating oil. Remember to use special lubricating oil, don’t use a kind of lubricating oil casually. If you use the wrong lubricating oil, the effect of lubricating oil will not be good. It is also possible that the lubricating oil will fall directly from the top when the lubricating oil is just applied. What a role.

Regularly replace the filter drier:

The filter drier should also be replaced. The filter drier is a very important component to ensure the normal circulation of the refrigerant. Water and refrigerant are incompatible with each other. If the system contains water, this will greatly affect the low-temperature freezing The operating efficiency of the unit, so it is very important to keep the system dry. If you want the internal dry, you need to replace the filter element inside the filter regularly.

Regularly check the pipeline for scale:

One of the usual maintenance of low-temperature refrigeration units should also pay attention to check whether the pipeline has deposited scale? If there is too much scale, it will significantly affect the heat transfer. The contact surface of cooling water will also shrink, the quantity will decrease, and the condensing pressure will increase. Usually, it is necessary to use tap water to use a water-cooled chiller. The quality of tap water in different regions of our country is different. Some are alkaline and some are alkaline. If the sex is small, some have more impurities, some have less impurities, and if there are more impurities for a long time, some very obvious scales will easily appear, and the effects we have just mentioned will appear.

To Sum Up

We need to carry out regular maintenance and inspection of the equipment, which can not only improve the efficiency of the machine but also save costs.

관련 권장 사항

-

How to deal with the installation of the hot and cold integrated control machine?

1256Since the thermocouple's thermal inertia causes the meter's indicated value to lag behind the measured temperature, this effect is particularly pronounced when performing rapid measurements. Therefore, thermocouples with thinner thermal electrodes...

세부 정보 보기 -

리액터 가열 및 냉각 장치의 주요 용도는 무엇인가요?

1055원자로 가열 및 냉각 장치는 고순도 금속, 희귀 물질 정제, 실험실 환경 시뮬레이션, 마그네트론 스퍼터링, 진공 코팅 및 기타 산업에 적합합니다. 대형 극저온 펌프 장치는 냉각 효과를 제공할 수 있습니다.

세부 정보 보기 -

스테인리스 스틸 반응기 및 유리 반응기를 위한 온도 제어 지침

1221반응기는 산업 생산에서 일종의 반응 장비입니다. 일반적으로 냉장 또는 가열해야 합니다. 온도가 적합한지 여부는 반응 효과에 직접적인 영향을 미칩니다. 따라서 조건이 허용되는 경우 일반적으로 ...

세부 정보 보기 -

아케마 2018에 참가하는 LNEYA

8772018년 6월 11일부터 15일까지 독일 프랑크푸르트 암 마인에서 열리는 공정 산업을 위한 세계 포럼 및 선도 전시회인 ACHEMA에 참가할 예정입니다(자세한 정보는 곧 공개될 예정입니다),

세부 정보 보기

LNEYA 산업용 냉각기 제조업체 공급 업체

LNEYA 산업용 냉각기 제조업체 공급 업체