Reactor Thermal Control Unit and Solutions for Chemicals

Temperature control is a process in which the temperature of a substance or a change in temperature is measured or otherwise detected, and the transfer of thermal energy into or out of the space or substance is adjusted to achieve the desired temperature.

When dealing with pharmaceutical production, maintaining accurate temperature control is critical. Starting with research throughout production, precise temperature control is required at every stage of the process. We fully understand the importance of process cooling, and simple temperature fluctuations (positive and negative) can ruin research or production.

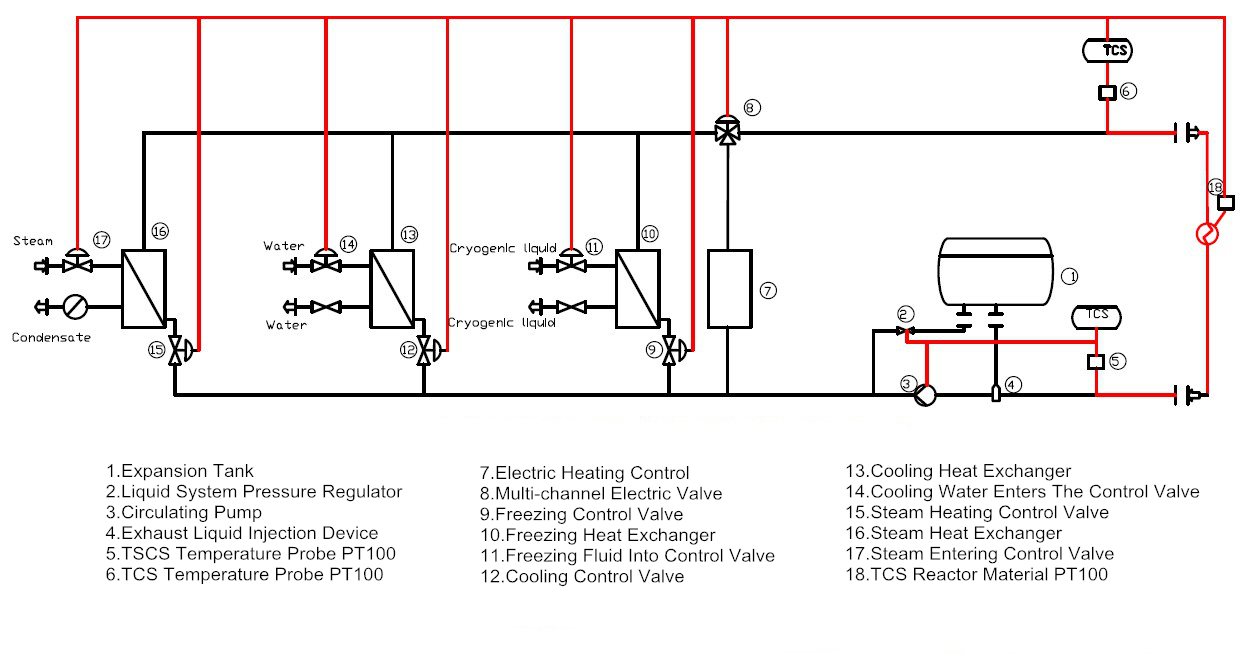

Our TCU can meet all your heating, cooling and temperature control needs for your chemical or pharmaceutical reactor. The LNEYA-TCU temperature control system can utilize existing thermal energy (such as steam, cooling water and ultra-low temperature liquids-the “primary system”) infrastructure integration to achieve dynamic temperature control of the equipment temperature in a single fluid system or a secondary circuit. This only completes the flow of a heat transfer liquid into the jacket of the reaction vessel (rather than directly into the steam, cooling water or cryogenic liquid), and the temperature of the entire reaction process is controlled by calculation.

From -120°C for cryogenic pharmaceutical applications to 300°C for chemical applications, the maximum temperature can be set according to the supplier’s heating or cooling source. The maximum temperature range can be set using a glycol water formula. Through three-point sampling (material temperature point, outlet temperature of temperature control system, inlet temperature of temperature control system), and our own model-free self-building algorithm and general anti-lag cascade algorithm, the problem of large drug delays is solved. Chemical temperature control . Our SR series and ZLF series are completely suitable for low temperature reaction, synthesis, separation process, pilot plant, reactor system, autoclave, combinatorial chemistry, etc.

This will increase product profitability and reactor utilization, and reduce energy and plant operating costs. Our TCU is fully automated and easy to operate. The temperature control accuracy of the product is ± 0.5 ° C, and the cooling power can be provided from 0.5 kW to 1200 kW.

The picture below shows the TCU thermal control unit customized by domestic customers

관련 권장 사항

-

소음이있는 스크류 냉각기 공장은 제때 점검하고 수리해야합니다.

1054산업용 스크류 칠러 공장을 사용하기 전에 부품 검사, 구성, 소음 등과 같은 모든 측면을 점검합니다. 사용 중 스크류 칠러에서 소음이 발생하면 어떻게 해야 하나요? 수리할 사람이 필요합니까? ...

세부 정보 보기 -

The existence of distillation and temp. control during distillation–SUNDI dynamic temp. control

1020Distillation exists in industries such as biopharmaceutical and petrochemical industries. Laboratory distillation includes vacuum distillation, short-path distillation, thin-film distillation, steam distillation, batch distillation, azeotropic dis...

세부 정보 보기 -

신에너지 자동차 모터 종합 테스트 시스템

1180LNEYA 신에너지 자동차 모터 통합 테스트 시스템을 실행할 때 제어판 설정이 필요합니다. 설정시 사용자가 사용 방법을 모르는 경우 설명서를 확인하여 사용할 수 있습니다. 새로운 에너지의 지표 ...

세부 정보 보기 -

공정 엔지니어링에서 동적 온도 제어 시스템의 온도 제어

947화학 산업, 특히 공정 엔지니어링에서는 많은 공정이 온도에 묶여 있거나 특정 온도 제어 애플리케이션에 의해 지원될 수 있으므로 효율성이 높아집니다. 후자의 예로는 연속 온도 제어가 있습니다.

세부 정보 보기

LNEYA 산업용 냉각기 제조업체 공급 업체

LNEYA 산업용 냉각기 제조업체 공급 업체