냉각 온도 조절기 냉각기가 갑자기 시작되지 않는 이유

If there are any unexpected situations during the use of the cooling thermostat Chiller, it is important to promptly identify the specific reasons before resolving them, in order to effectively address various issues. For example, what is the reason why the cooling thermostat Chiller suddenly fails to start during operation?

One、 The reason why the cooling thermostat Chiller cannot start

1. The main reason is that during the operation of the system, the pressure at the equipment inlet is low, which cannot meet the basic operating conditions, leading to the problem of not being able to start.

2. According to the instructions for the configuration of the refrigeration thermostat Chiller, it can be understood that it is mainly caused by the idle water pump and other reasons. As long as the air in each system of the refrigeration thermostat Chiller is released, it can meet the suitable operating environment and achieve the purpose of starting the refrigeration thermostat Chiller.

3. The issue of stress. After experiencing varying degrees of startup difficulties, it is necessary to complete the maintenance of the refrigeration thermostat Chiller according to actual needs.

4. To ensure smooth operation, it is necessary to effectively control the inlet and outlet of the water pump during the use of the refrigeration thermostat Chiller. As the air is continuously eliminated, any malfunctions that cannot be started can be resolved.

Two、 Handling methods for encountering high-voltage faults

1. Due to insufficient cooling water flow, the rated water flow cannot be reached. The main manifestation is that the pressure difference between the inlet and outlet water of the unit decreases and the temperature difference increases. The reason for insufficient water flow is due to a lack of water or air in the system. The solution is to install an exhaust valve at a high position in the pipeline for exhaust; If the pipeline filter is blocked or too fine, and the permeability is limited, a suitable filter should be selected and the filter screen should be cleaned regularly; The selection of water pumps is relatively small and not compatible with the system. Excessive refrigerant charge.

2. This situation usually occurs after maintenance, manifested as high suction and exhaust pressure, balance pressure, and high operating current of the compressor. It should be deflated under rated operating conditions based on suction and exhaust pressure, balance pressure, and operating current until normal, so it is still necessary to regularly check.

관련 권장 사항

-

Working Principle of Glycol Chiller

1177For the low-temperature chiller using ethylene glycol solution, wecall it glycol chiller. Its outlet water temperature is generally below - 10 ℃, and the specific temperature requirements shall be subject to theneeds of users. Glycol chillers ar...

세부 정보 보기 -

Performance Characteristics of 30 HP Water Cooled Chiller

1105The 30p water cooled chiller is an industrial water chiller with a horsepower of 30 HP. The water-cooled industrial water chiller must rely on the cooling water tower for work, while the air-cooled industrial water chiller uses its own fan for coo...

세부 정보 보기 -

냉동 및 난방 순환 시스템에 TCU 적용

1240의약품 합성 및 정밀 화학 작업 과정에서 우리는 종종 산화 반응 및 산-염기 중화와 같은 강력한 발열 반응에 직면합니다. 이러한 강한 발열 반응의 경우 제어가 부적절하거나 제어가 부적절하면 ...

세부 정보 보기 -

High and low temperature equipment manufacturers analyze expansion valve knowledge

1148The expansion valve is an important accessory in the high and low temperature integrated machine. The manufacturer tells you that there are various kinds of expansion valves, and different expansion valves have different differences. The high and ...

세부 정보 보기

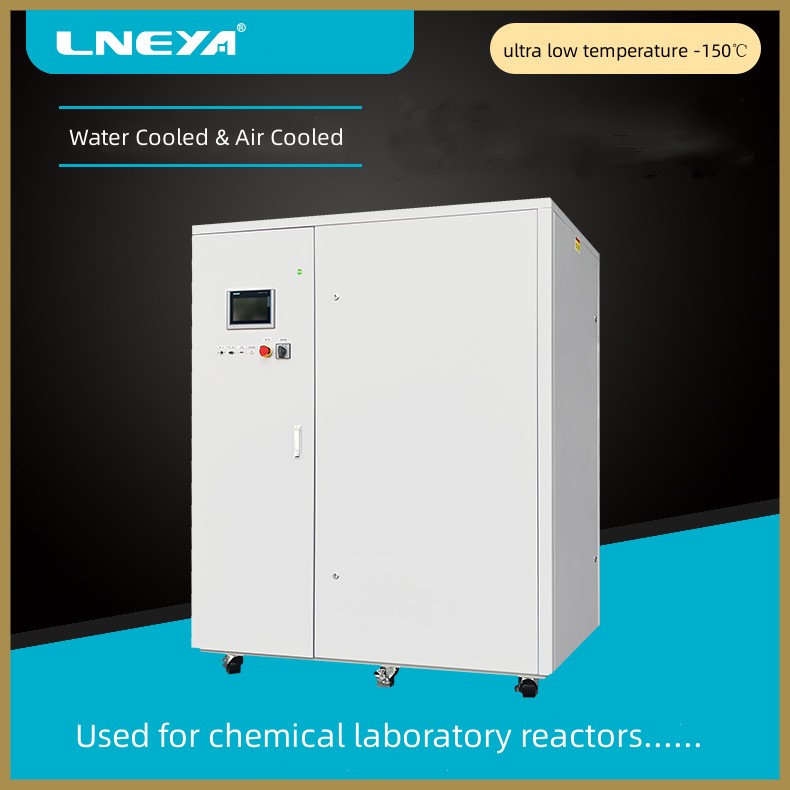

LNEYA 산업용 냉각기 제조업체 공급 업체

LNEYA 산업용 냉각기 제조업체 공급 업체