칩 생산 고온 및 저온 에이징 테스트 챔버의 기능은 무엇인가요?

현재 칩 웨이퍼 생산 업계는 전례 없는 도전과 변화에 직면해 있습니다. 기술 외에도 생산량은 항상 업계의 관심사였습니다. 칩의 탄생에는 많은 공정이 필요하고 좋은 칩이 필요하다는 것을 우리 모두 알고 있습니다.

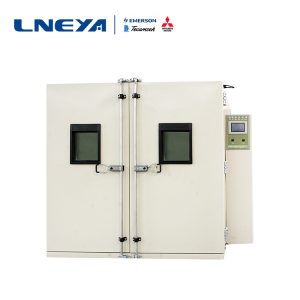

The test of the chip industry is related to the quality of each chip version, so the chip high and low temperature aging test box is very necessary in the development of the chip industry.

The complexity of chips is getting higher and higher. In order to ensure that there are no problems with the chips that leave the factory, it is necessary to test before leaving the factory to ensure functional integrity. As the chip is a mass-produced thing, large-scale automated testing is Weiyi’s solution. It is impossible to accomplish such a task by manual or bench test. The chip high and low temperature aging test box is actually a relatively large category, which is generally divided into wafer test and final test from the test objects. The objects are chips that have not been packaged and chips that have been packaged. Why is it divided into two paragraphs? Simply put, because packaging also has a cost, in order to save costs as much as possible, a part of the test may be performed before the chip is packaged to exclude some broken chips. In order to ensure that the chips shipped from the factory are all right, the final test, that is, the FT test, is an interception, and it is also a necessary link.

Generally speaking, the chip high and low temperature aging test box includes pin connectivity test, leakage current test, some DC (direct current) test, functional test (functional test), Trim test, and some other tests according to the chip type. For example, AD/DA will have some special test types. The purpose of chip testing is to save costs as much as possible while finding the correct chips. Therefore, defects that are easy to detect or more common will be tested first. Generally speaking, the first thing we will do is connectivity test, which we call continuity test. This is to check whether the connectivity of each pin is normal.

The chip high and low temperature aging test box mainly saves costs for the chip industry, and can give priority to selecting good quality chips.

관련 권장 사항

-

Main differences between indoor chillers and outdoor chillers

917Although indoor chillers and outdoor chillers are both devices used to provide cold water to meet specific cooling needs, they have significant differences in design, installation location, working environment, and heat dissipation methods...

세부 정보 보기 -

용매 설명 및 증류 냉각 장비 설치

1143During the chemical reaction, most of the chemical reactions are carried out in solvents. Solvent is an important medium, which can make all kinds of molecules participating in the reaction evenly distributed, increase the chance of collision and ...

세부 정보 보기 -

Step-by-step test box brand advantage description

1294The walk-in test box is developed and produced by LNEYA. It is specialized in pharmaceutical production technology and provides customers with various models of brands. Next, we will introduce the next step-in test box. Welcome to refer to and lea...

세부 정보 보기 -

Temperature control of integrated circuit/chip wafer quality and reliability test items

1296The most basic part of making a chip is design-tape-package-test. The chip cost structure is generally 20% of labor cost, 40% of tape, 35% of package, and 5% of test. The test is actually the most in all aspects of the chip. "Cheap" step, but the...

세부 정보 보기

LNEYA 산업용 냉각기 제조업체 공급 업체

LNEYA 산업용 냉각기 제조업체 공급 업체