Advantages of bearing cryogenic treatment equipment

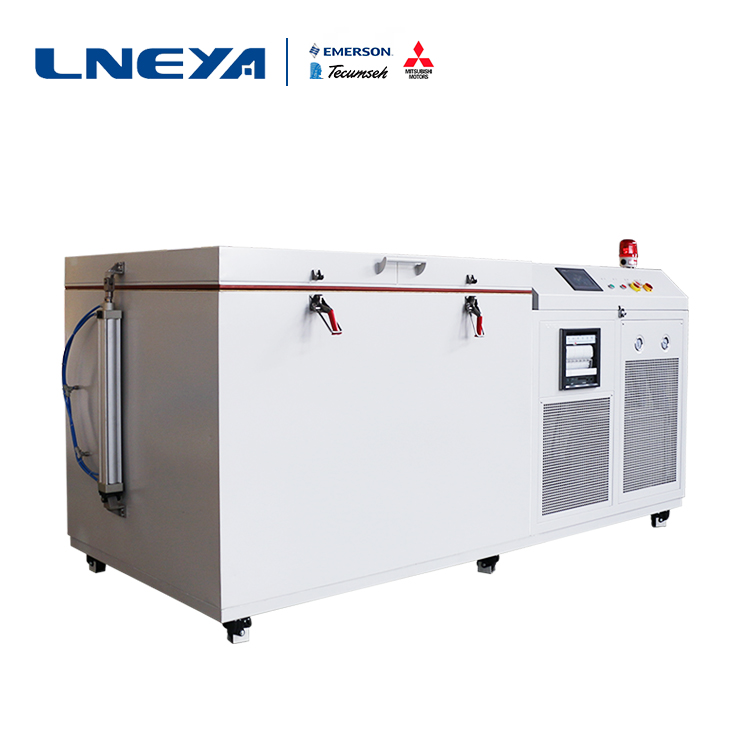

One of the names of the ultra-low temperature freezer is the bearing cryogenic treatment equipment. Wuxi Guanya LNEYA’s ultra-low temperature freezer is designed for large volume ratio; large capacity bearing capacity design; can set the temperature difference between turning on the compressor and turning off the compressor;

A variety of fault alarms (over temperature alarm, sensor alarm, high pressure alarm, compressor overheat alarm).

Cryogenic treatment is a continuation of the workpiece cooling process after quenching. The application in the mold industry is mainly reflected in the application of cryogenic technology in cold work die steel and high speed steel, bearing steel, cold work die and mold parts.

The advantages of cryogenic treatment are as follows:

1. Improve the hardness and strength of the workpiece

2. Guarantee the dimensional accuracy of the workpiece

3. Improve the wear resistance of the workpiece

4. Improve the impact toughness of the workpiece

5. Improve the stress distribution inside the workpiece and improve the fatigue strength

6. Improve the corrosion resistance of the workpiece.

Bearing cryogenic treatment equipment product structure:

The bearing cryogenic treatment equipment adopts 7-inch color touch screen (display set temperature, measurement temperature), temperature curve record, U disk data export, format is excel table, fault record, real-time monitoring temperature change inside the box, with manual and automatic double operation function . The equipment uses liquid nitrogen as the cooling medium, and the stainless steel cabinet is beautiful and durable, and is insulated by high-quality high-density polyurethane foam insulation layer. The system structure is reasonable, the manufacturing process is standardized, the components are arranged compactly, the operation is simple and powerful, and the humanized communication interface; the low temperature can reach -150 ° C, and the cooling speed is fast. The ultra-low temperature cryogenic test chamber adopts (developed by itself) Guanya company mixed refrigerant, which makes the process of constant temperature and temperature drop of the product even and stable.

Application range:

It is mainly used in industrial cold treatment to precipitate uniform, fine and dispersed carbides generated on the metal structure matrix. The appearance of such a carbide will bring about a significant increase in the wear resistance and friction properties of the metal, and the hardness will also increase, and will directly increase the life of the wear member. The ideal product to replace liquid nitrogen.

It is used for shrinkage of copper sleeves, bearings, etc., and is widely used in precision mechanical assembly. It is used in ultra-low temperature testing of large equipment (automobiles, large construction machinery, aircraft components, aerospace equipment components, military equipment components).

관련 권장 사항

-

Equipment attention points of laboratory high and low temperature cycle equipment manufacturers

1113In the laboratory, a wide range of experimental instruments are widely used. When the experimental instruments are in operation, they are inseparable from the high-low temperature circulating device refrigeration heating equipment. What should be ...

세부 정보 보기 -

Low temperature refrigeration unit maintenance inspection

1130Low-temperature refrigeration units usually need to do a maintenance. After the maintenance is done, it is not easy to fail, and there will be more markets. If it is not easy to fail, it will not stop working, which is equivalent to saving the com...

세부 정보 보기 -

Pharmaceutical industry reactor supporting equipment high and low temperature thermostat

965The high and low temperature thermostat is a temperature control device used in the pharmaceutical industry to heat the reactor for different time periods. It is simple and convenient to operate, and can quickly improve the temperature rise and fa...

세부 정보 보기 -

Temperature requirements for ion implantation chillers in semiconductor manufacturing processes

883Ion implantation is an important step in semiconductor manufacturing processes to precisely dope and control the electrical properties of semiconductor materials by implanting high-energy ions into them. This process generates a lot of hea...

세부 정보 보기

LNEYA 산업용 냉각기 제조업체 공급 업체

LNEYA 산업용 냉각기 제조업체 공급 업체