Troubleshoot the main points of failure of the high and low temperature cooling system

When the industrial high and low temperature cooling system is in use, what is the general reason if the temperature cannot drop down? How should we deal with such failures?

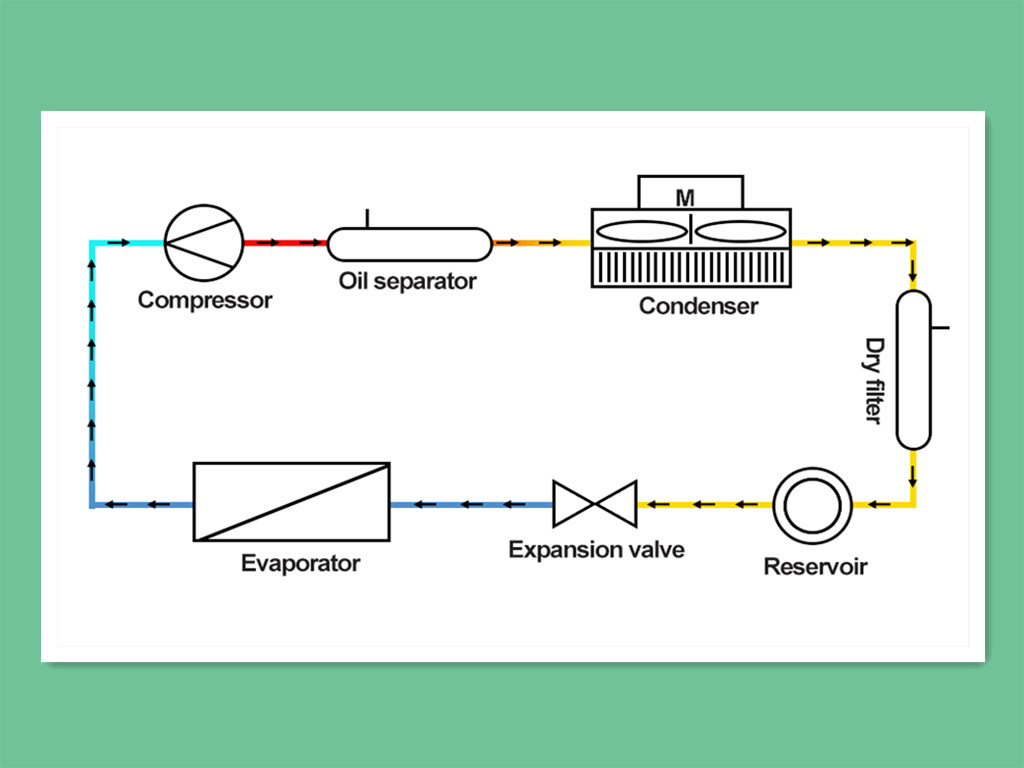

Let’s first analyze the principles and methods of industrial cooling. The circulating heat transfer medium is different. Generally, the high and low temperature cooling system industry mostly uses direct cooling, while indirect cooling is used, with plate heat exchangers or oil coolers installed inside. In other devices, the heat medium and cooling water source in the system exchange heat in the heat exchanger to reduce the temperature of the medium.

The temperature of the high and low temperature cooling system cannot be reduced. Generally, we conduct inspection and maintenance from the following aspects:

1. The cooling solenoid valve is damaged: it is necessary to check whether the solenoid valve coil can work normally, if it is damaged, it needs to be replaced; the panel does not output a cooling signal, carefully check the circuit or use the component replacement method to check.

2. Circuit failure: Check the circuit part of the system, the cooling water inlet or outlet pipeline is blocked: check whether the valve in the cooling water pipeline is fully opened, and ensure that the flow and pressure of the cooling water are sufficient, and the heating contactor is stuck, Always heating: observe the pull-in state of the contactor, and worsen damaged electrical parts.

In addition to troubleshooting the above two possible causes of failure, we also need to check whether the cooling plate is replaced or the cooling exchanger is blocked.

The advantage of using indirect cooling is that it has high temperature control accuracy and strong adaptability. It can be applied to the temperature control of high and low temperature cooling system industries. And because the heat transfer medium is cooled first, the cooling impact on the temperature control equipment is relatively small. Of course The disadvantage is that the cooling speed is relatively slow, and the price is more expensive than direct cooling.

관련 권장 사항

-

Precautions for installing reactor refrigeration and heating cycle equipment

1552reactor temperature control unit installing

세부 정보 보기 -

Product description for ultra-low temperature refrigeration

1096Technical parameters (low temperature cold storage project within 100 cubic meters) of Ultra-Low Temp Cold Storage 1. Medical cold storage temperature range(℃):Low-temperature storage library: -20°C to -50°C Preservation of plasma, biological ma...

세부 정보 보기 -

"2021 고품질 개발상" 수상

16952022년 5월 8일 오후, 우시시 홍산 거리에서 2020년 연례 요약 및 표창 회의가 열렸습니다. 우시관야 항온냉동기술유한공사(Wuxi Guanya Constant Temperature Refrigeration Technology Co. (LNEYA)가 "2020 우수 공헌상"을 수상했습니다.

세부 정보 보기 -

40 스크류 냉동고의 기밀성을 확인하는 방법은 무엇인가요?

1280기밀성은 전체 40 핀 스크류 냉동고의 냉각 효과와 관련이 있습니다. 따라서 LushiA (LNEYA)의 40 핀 스크류 냉동고 제조업체는 사용자에게 4 가지 검사를 수행 할 것을 권장합니다. 이 테스트는 ...

세부 정보 보기

LNEYA 산업용 냉각기 제조업체 공급 업체

LNEYA 산업용 냉각기 제조업체 공급 업체