집적 회로 온도 제어 장치 연구 설명

At present, integrated circuit temperature control is used in the integrated circuit, semiconductor, and chip industries. Then, for the testing needs of such industries, integrated circuit temperature control is necessary.

At present, there are several problems in the cooling equipment of integrated circuit temperature control: the temperature is not stable enough, the flow is not stable enough, and communication with the main monitoring system cannot be connected. Wuxi Guanya integrated circuit temperature control temperature range: -45 ° C -250 ° C, the flow can be roughly controlled within a certain error range of the set value.

The flow rate of the integrated circuit temperature control can be adjusted by means of bypass and resistance matching, and the temperature can be controlled by controlling the amount of cooling and the amount of heating. The cooling capacity can be controlled by a variable frequency refrigeration unit or by using a freon flow that is bypassed in front of the evaporator and bypassed to participate in heat exchange. The key technology lies in the design of the PLC control program. At present, a thermoelectric refrigeration method can be employed to improve the stability of the temperature of the cooling equipment. Since the cooling capacity of the thermoelectric refrigeration module can be realized by controlling its current, the control circuit is relatively simple and easy to achieve high precision.

The so-called intelligent transformation of integrated circuit temperature control means that the cooling device is equipped with a digital port and has the ability to communicate with the computer I/O. The flow, temperature, pressure and operating status of the device can be transmitted to the main control computer, and the test personnel The various parameters and operation of the device can be controlled by the master computer. Integrated circuit temperature control not only improves the level of development of our products, but more importantly, it can greatly shorten our development cycle. We should thoroughly clarify the demand target, track the advanced foreign technology on the basis of the previous CAT technology, and adhere to the working methods of easy and difficult, social collaboration to complete this technical work.

Integrated circuit temperature control technology is a relatively wide temperature control technology. For the integrated circuit industry, its existence is also insignificant, and it is also important to improve the effectiveness of integrated circuits.

(참고: 일부 원본 콘텐츠는 관련 논문에서 발췌한 것입니다. 저작권을 침해한 경우 제때 삭제해 주시기 바랍니다.)

관련 권장 사항

-

초고온 소재 냉온 충격 박스 냉장 오일

1228초고온 재료 충격 시험 챔버 테스트 장치의 증발기에 오일이 너무 많이 얼어 냉각이 불충분하고 냉각이 느려질 수 있습니다. 초고온 재료의 증발기에 저장된 오일은 ...

세부 정보 보기 -

What instruments in biopharmaceutical processes require cooling water systems?

886In biopharmaceutical processes, many critical equipment and instruments require cooling water systems to maintain their normal operation and process temperature control. The following are some common types of equipment that require cooling w...

세부 정보 보기 -

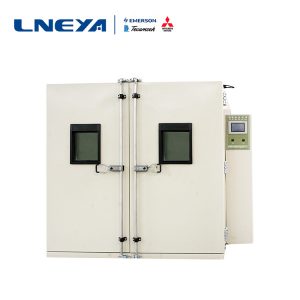

Description of the characteristics of the LNEYA walk-in test chamber

893Wide temperature control range can meet the user's various needs.Unique balanced temperature control method, a stable and balanced heating capacity can be used for high precision and high stable temperature control.The temperature displayed by tou...

세부 정보 보기 -

Wuxi Guanya Low Temperature Test Chamber With 12 Years Brand ranked the top ten in China!

729Throughout the low temperature test chamber industry, there are no less than thousands of manufacturers. Almost every family is confident about their products, but from the feedback complaints and after-sales situation of users, Wuxi Guanya Thermo...

세부 정보 보기

LNEYA 산업용 냉각기 제조업체 공급 업체

LNEYA 산업용 냉각기 제조업체 공급 업체