Detailed description of piping of refrigeration and heating cycle equipment

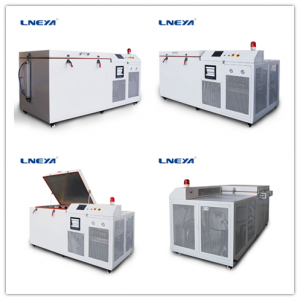

When the refrigeration and heating cycle equipment is in operation, the user will find that whether or not the fully enclosed pipeline affects the overall performance. The LNEYA refrigeration and heating cycle equipment adopts a fully enclosed cycle pipeline, and there is no oil mist and water vapor during high and low temperature operation, which is continuously improved. Operational efficiency, so what is important in piping design?

The refrigeration and heating cycle equipment adopts a fully enclosed pipeline design and a high-efficiency plate heat exchanger, which reduces the demand for heat transfer fluid while increasing the heat utilization rate of the system to achieve rapid temperature rise and fall. The heat transfer medium is in a closed system with an expansion vessel. The heat transfer medium in the expansion vessel does not participate in the circulation. Whether it is high or low temperature, the temperature of the expansion tank is from room temperature to 60 degrees, which can reduce the absorption of moisture and volatilization of the heat transfer medium during operation. risk.

The refrigeration and heating cycle equipment should keep the entire system of the refrigeration and heating cycle equipment group clean after installing the compressor welding pipes to avoid welding slag and other impurities in the refrigeration and heating cycle equipment system, causing serious malfunctions during compressor operation. Vibration is unavoidable during operation. In order to reduce the vibration of the pipeline, it is recommended to use copper pipes as suction and exhaust pipes. In this way, when the compressor is running normally, the copper pipe in the pipeline can reduce the vibration. If steel pipes are to be used for the piping in the system, proper welding techniques are very important to avoid stress in the piping system. These internal stresses will cause resonance and noise, which will reduce the service life of the compressor.

After the refrigeration and heating cycle equipment is welded, the oxidized impurities and debris generated by the welding of the pipeline should be removed in time. If these impurities enter the compressor, it may cause the oil filter to block and make the lubrication system and the capacity adjustment system fail. If the suction and discharge flanges of the compressor of the refrigeration heating cycle equipment are made of cast steel, they can be directly welded to the pipeline. After welding, it should be cooled in the atmosphere, and cooling with water is prohibited.

LNEYA refrigeration and heating cycle equipment is different from other manufacturers in terms of overall performance. Different manufacturers have different prices and configurations, so you need to pay attention to the price of one product.

관련 권장 사항

-

How to solve the phenomenon of ultra-low temperature freezer card cylinder?

1486If the ultra-low temperature freezer room fails during operation, it needs to be solved in time. If it is similar to the related phenomenon, it may be that the frozen oil does not come up, and the operator needs to solve it in time. Ultra-low temp...

세부 정보 보기 -

자동차 파워 모듈 냉각 시스템의 작동 파라미터 및 작동 조건 분석

1200선택하기 전에 자동차 전력 모듈 냉각 시스템의 작동 매개 변수 및 작동 조건과 관련된 요인을 알아야 합니다. 그렇다면 어떤 측면에서? 1. 증발 압력 및 증발 온도 작동 중 ...

세부 정보 보기 -

진공 펌프 온도 제어 시스템 사용에 대한 오해

968When using the vacuum pump temperature control system, only the correct operation method can ensure the normal and stable operation of the equipment. If there are many wrong operation behaviors, it will directly affect the normal use of the equipm...

세부 정보 보기 -

Automotive antifreeze test test temperature control system

1053When it comes to car antifreeze, we all know that its main function is to prevent the coolant from freezing and cracking the radiator and freezing the engine cylinder block or cover when we stop in the cold winter. Make the cooling system in the ...

세부 정보 보기

LNEYA 산업용 냉각기 제조업체 공급 업체

LNEYA 산업용 냉각기 제조업체 공급 업체