Purchasing a special chiller for etching machine and precautions for operation

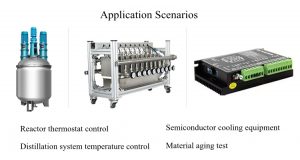

The special chiller for etching machine is used for testing of components, chips, etc. These industries are more supporting use, so what aspects should be paid attention to when choosing the chiller for etching machine drilling? What should I pay attention to when operating?

Key points for purchasing special chiller for etching machine:

1. When choosing a special chiller for etching machines, companies need to choose according to their own working conditions, and avoid choosing too small or too large equipment

2. The key parts of the internal parts of the special chiller for the etching machine should be paid attention to, especially the performance of the main parts such as the compressor and the evaporator. Once the quality of the key parts is poor, the overall performance of the equipment will be affected.

3. After determining the main performance configuration of the special chiller for the etching machine, you can compare multiple quotations, pay attention to the control of the purchase cost and the comprehensive comparison of performance, and select the appropriate unit.

4. Be careful not to buy a refurbished machine to avoid various failures during use

Precautions for the operation of the special chiller for the etching machine:

1. Before installing the special chiller for the etching machine, check whether the equipment is damaged and whether it is installed in a suitable position

2. It is recommended to choose a flat ground with normal room temperature for the installation location of the special chiller for the etching machine, and leave enough space around for heat dissipation.

3. The chiller dedicated to the etching machine should pay attention to the stability of the chilled water under load, and the water flow speed of the evaporator condenser should be kept within the range;

4. The design and installation of the cooling water pipe of the unit need to be carried out according to the working conditions. The location of the chilled water pump needs to ensure its positive pressure and flow, and the piping should pay attention to its shock-absorbing pipe to ensure proper flexibility;

5. The special chiller for the etching machine should be firm to avoid pressure and danger during the operation of the special chiller for the etching machine;

6. The special chiller for the etching machine needs to clean the pipes, condensers and evaporators regularly to ensure operating performance.

To Sum Up

When choosing a special chiller for etching machine, you need to find a manufacturer with after-sales service to purchase. Such manufacturers will provide corresponding product manuals when the equipment leaves the factory. Users can use and maintain according to the product manuals.

관련 권장 사항

-

Maintenance knowledge of 12HP (8.9kW) low temperature chiller

1194The user can arrange the operator to learn about the daily maintenance knowledge of the 12HP (8.9kW) low temperature chiller after purchase. It can not only improve the company's product quality, improve production efficiency, but also extend the ...

세부 정보 보기 -

원자로의 자동 온도 제어 시스템 고장을 해결하는 방법은 무엇입니까?

1215원자로의 자동 온도 제어 시스템의 성능은 매우 중요합니다. 시작할 수없는 고장이 발생하면 가능한 한 빨리 해결해야하며, 그렇지 않으면 제어 할 수없는 온도가 원자로에 영향을 미칩니다.

세부 정보 보기 -

신에너지 차량 배터리 테스트 시스템에서 냉매의 중요성

1305새로운 에너지 차량 배터리 테스트 시스템에서 냉매의 유량이 극히 적으면 스로틀 밸브 후단의 첫 번째 확장 가능한 공간에서 냉매가 팽창하기 시작합니다. 대부분의 후단 시업은 ...

세부 정보 보기 -

진공 펌프 온도 제어 시스템 사용에 대한 오해

964When using the vacuum pump temperature control system, only the correct operation method can ensure the normal and stable operation of the equipment. If there are many wrong operation behaviors, it will directly affect the normal use of the equipm...

세부 정보 보기

LNEYA 산업용 냉각기 제조업체 공급 업체

LNEYA 산업용 냉각기 제조업체 공급 업체