산업용 재순환 냉각기의 구조적 특성

In the chemical reaction, there are strict requirements for the reaction temperature. It is necessary to raise the temperature to an appropriate temperature to carry out the chemical reaction smoothly. After the reaction, the temperature in the reactor must be reduced to room temperature. The existing heating system of the reactor is relatively simple, so the process of reducing the temperature in the reactor to room temperature takes a long time, and the thermal energy can not be used reasonably, resulting in a waste of some resources. Therefore, a temperature control system for rapid heating or cooling is required.

The reactor cooling and heating recirculating chiller is a typical cooling recirculating chiller with heating function. It is suitable for the laboratory and can ensure the repeatability of the experimental results. The operating temperature range is – 45 ℃to 250 ℃. the reactor refrigeration and heating recirculating chiller produced by our company has compact structure, small floor area and environmental protection. It can be placed in the ventilation place of the laboratory or used inside the equipment.

Refrigeration heating recirculating chiller is a temperature controller integrating refrigeration and heating. It is composed of two systems, two computer PC boards, each controlling the corresponding system, and automatically adjusting heating or cooling through heat transfer oil circulation according to process requirements. It consists of pump, heating pipe, cooling heat exchanger, refrigeration system, temperature control system, pipeline and frame. The heat transfer oil flows between the heat medium pipe of the unit and the jacket or coil of the reactor. The circulating pump, heat transfer oil pipe, heating device and cooling device constitute the basic circuit of the heat medium.

Many chemical reactions are accompanied by a large number of endothermic or exothermic phenomena. Temperature is an important process parameter in the production process. Our recirculating chillers provide a variety of modes from small refrigeration power to large refrigeration power, from laboratory to production site, so as to provide continuous and stable process temperature control.

관련 권장 사항

-

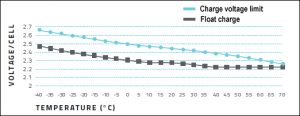

Is it right to extend battery life by lowering the ambient temperature?

1006The battery can work in a wide temperature range, but this does not allow the battery to be charged under high temperature conditions. The charging process is more delicate than the discharging process, and extreme care must be taken. Extreme cold...

세부 정보 보기 -

상세한 전기 자동차 모터 테스트 및 테스트 시스템

1078새로운 에너지 차량은 동력 시스템, 구동 시스템, 제어 시스템 통합 테스트 역량과 전자 제어 테스트 시스템 기능 테스트 역량을 갖춰야 합니다. 부품 제조업체의 경우 이러한 테스트 개발 능력은 ...

세부 정보 보기 -

Introduction of temperature control equipment for cannabis extraction

1086CO2 is a unique solvent because its dissolving power can be changed by simply adjusting the temperature and pressure during the extraction process. When the pressure and temperature of CO2 are higher than 1083 psi and at 88F, CO2 is considered sup...

세부 정보 보기 -

LNEYA 산업용 냉각기 제조업체 공급 업체

LNEYA 산업용 냉각기 제조업체 공급 업체