제품 특징

제품 매개변수

| Mode | DR-300 | DR-600 | DR-1200 |

| 압력 범위 | 0.65~1.0Mpa | ||

| 이슬점 온도 | -70℃ | ||

| Gas processing capacity | 425L/분 | 900L/분 | 1750L/분 |

| 완성된 가스 볼륨 | 300L/분 | 600L/분 | 1200L/분 |

| 연결 크기 | ZG1/2 | ZG1/2 | ZG3/4 |

| 전원 | 220V 15W | ||

| 치수 cm | 200*180*1250 | 450*180*1250 | 450*180*1250 |

Distributed gas sources used in sensors, semiconductor manufacturing, film and packaging material licensing, powder material transportation, spraying systems, food industry, pharmaceutical industry, etc. that require -80℃ low dew point drying and cleaning.

Additional filtration of oil and particulate matter, with airflow passing through a filtration level of 0.01 μm, the pre filter prevents the desiccant from being contaminated by dust and oil (which greatly shortens the lifespan of the desiccant).

The compressed air dryer consists of multiple sets of filter cartridges filled with desiccants. The compressed air in the form of mist alternately flows through multiple sets of filter elements, and the moisture in the air will accumulate on the surface of the dryer. After the filtration process reaches a predetermined duration, the airflow will switch to other filter elements, and a portion of the airflow (discharge airflow) will be used to regenerate the dryer of the first filter element. The flushing airflow will be released into the atmosphere. The service life of desiccants is approximately 15000 working hours.

Product Advantages

- 효율적인 생산 안정성 및 반복성 결과;

- 판형 열교환기와 파이프라인 히터를 사용하여 냉각 및 난방 속도를 개선합니다;

- 매우 넓은 온도 범위로 액체 매체를 교체할 필요가 없습니다;

- 완전 밀폐형 시스템으로 열 전도성 액체의 수명을 연장합니다;

- 마그네틱 드라이브 펌프를 채택하여 샤프트 씰 누수 문제가 없습니다;

- 고온 냉각 기술, 압축기를 직접 시동하여 300℃에서 냉각합니다.

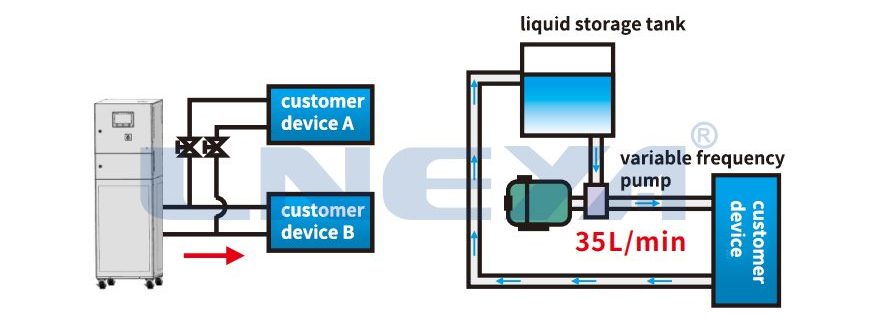

가변 주파수 펌프는 순환 유압 및 유량을 조절할 수 있습니다.

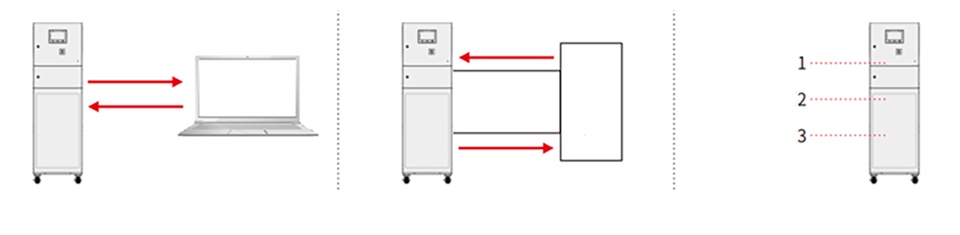

client output signal

Communication function

애플리케이션

Such as chillers that control the processing temperature on the Fab equipments.

Cooling of CMOS/CCD sensors in semiconductor metrology systems.

Recirculating Chiller for semiconductor metering AOI system.

주로 에칭 장비용으로 설계된 단일 채널 공랭식 쿨러입니다. 챔버 측벽에 독립적인 온도 제어를 제공하는 데 사용됩니다.

Used for plasma bevel etch and deposition; Thermal Atomic Layer Etching of Metal Tungsten.

LNEYA provides customized Chiller services

custom chiller sizes

Whether it is portable, compact, large and small chillers, we can custom design them according to your requirements. No matter how many tons of chiller you need, we can create the best solution.

custom chiller types

We provide chillers of various refrigeration types, including but not limited to air-cooled, water-cooled and evaporative-condensing chillers. Regardless of the type of refrigeration compressor, we can design it according to your requirements.

custom temperature ranges

We can create a custom solution for temperatures from -150℃ to +350℃. Custom temperature ranges for specific industries.

custom chiller voltage

Customize chiller voltage and phase according to your needs. Optional 110V/60HZ, 220V/60HZ, 380V/50HZ, 220V/50HZ, 400V/50HZ, 460V/60HZ, 440V~480V/60HZ, etc.

LNEYA 공장 방문

온도 제어 공급업체로 엘니야를 선택하는 이유는 무엇인가요?

수년간의 경험

만족한 고객

m² 생산 면적

특허 기술

LNEYA 산업용 냉각기 제조업체 공급 업체

LNEYA 산업용 냉각기 제조업체 공급 업체