Micro-channel reactor thermostatically controlled air-cooled chiller compressor troubleshooting meth

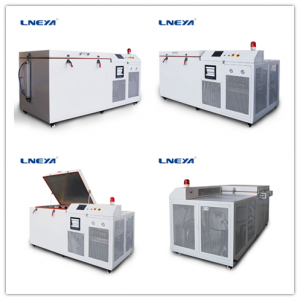

The air-cooled chiller is a temperature

control device that is widely used in the microchannel reactor industry. Wuxi

Guanya LNEYA has produced a cold and heat source thermostatically controlled

air-cooled chiller for the microchannel reactor industry. If the compressor

fails during operation, it needs to be investigated and solved in time.

To troubleshoot the micro-channel reactor

thermostatically controlled air-cooled chiller compressor, first check the

circuit part to see if the equipment power supply, voltage, and switch are

normal; see if the equipment power supply is powered, the voltage is normal,

and the switch contacts are good , Whether the power supply lacks phase. When

the equipment is not equipped with an ammeter or a voltmeter, a multimeter or a

tester can be used to check the power supply. When the power supply voltage is

too low, the compressor cannot be started.

If the compressor of the micro-channel

reactor thermostatically controlled air-cooled chiller adopts a piston

compressor, whether the big end bearing bush and the curved sleeve of the

connecting rod are caught. These may be caused by the excessively high exhaust

temperature during the previous operation, or it may be caused by the coking of

the lubricating oil, which causes the cylinder and the piston to stick

together, which prevents the compressor from starting.

Check the thermostatically controlled

air-cooled water chiller differential pressure relay and high and low voltage

relay of the microchannel reactor. When the oil pressure of the compressor is

abnormal, the compressor can be stopped. At the same time, when the compressor

discharge pressure and suction pressure are abnormal, neither of them can be

started or the compressor will quickly stop running after it has been started.

Check whether the amount of chilled water, cooling water, and water temperature

are normal. If the water volume is small and the water temperature is high, it

will cause the condensing pressure to rise sharply and the evaporation

temperature to drop rapidly. Due to the action of the unit protection

facilities, the unit often shuts down quickly.

Check whether the solenoid valves and

regulating valves related to the equipment are malfunctioning, and whether they

are opened or closed as required. Check whether there is a leakage of working

fluid in the temperature sensing bag of the temperature relay, or the

adjustment is wrong.

Before use, the corresponding preparations

must be done well in order to run efficiently.

관련 권장 사항

-

LNEYA 스크류 냉각기의 증발기 특성

1671스크류 칠러의 냉각 용량은 전체 장치의 에너지 소비 및 운영 경제성과 직접적인 관련이 있으므로 주목할 가치가 있습니다. 특히 콜드 스테이션을 설계 할 때 단일 냉각기가 없습니다.

세부 정보 보기 -

How to complete the temperature control equipment for the isolation reactor?

1027The reactor is a commonly used reactor in pharmaceutical and chemical production. The isolation reactor temperature control equipment is realized by controlling two doors, namely the heating water valve and the cooling water valve. The mixing of t...

세부 정보 보기 -

How to solve the phenomenon of ultra-low temperature freezer card cylinder?

1480If the ultra-low temperature freezer room fails during operation, it needs to be solved in time. If it is similar to the related phenomenon, it may be that the frozen oil does not come up, and the operator needs to solve it in time. Ultra-low temp...

세부 정보 보기 -

Main differences between indoor chillers and outdoor chillers

913Although indoor chillers and outdoor chillers are both devices used to provide cold water to meet specific cooling needs, they have significant differences in design, installation location, working environment, and heat dissipation methods...

세부 정보 보기

LNEYA 산업용 냉각기 제조업체 공급 업체

LNEYA 산업용 냉각기 제조업체 공급 업체