What aspects should be paid attention to when using laboratory cryogenic refrigeration circulators?

The compact circulating cooler is an economic model for routine laboratory applications. The instrument is cooled in the temperature range of -10 or 0°C to +40°C, and the temperature control accuracy can reach ±0.5°C. It is a good way to replace expensive tap water and is an ideal choice for basic cooling tasks. The lower acquisition cost means they can recover the cost in a short time.

The device has its own self-diagnostic function, and there are liquid inlet and outlet ports and switches on the back, and the filling port is located in the top groove, which is easy to operate. Another advantage is that the ventilation slots are located at the front and back, so the device can be placed directly in another location (saving space). It can be combined with rotary evaporators, glass reactors and other instruments to carry out various chemical reactions.

If the laboratory’s small low-temperature refrigeration circulator is faulty, its operating data must be abnormal during the operation of the equipment. By checking the abnormal data, it can be judged whether it is in a faulty operating state. Companies can find and quickly and effectively deal with various common faults in a timely manner, so the cost of long-term operation of the laboratory small cryogenic refrigeration circulator is very low.

Precautions during use: In the process of operating the small low-temperature refrigeration circulator in the laboratory, it is necessary for the company to regularly conduct certain tests on the equipment. Careful statistics of various operating data can determine whether the operating status of the equipment is stable, and a suitable operating plan can be adjusted in time to prevent more failures, thereby creating conditions for extending the service life of the equipment and reducing costs. low.

관련 권장 사항

-

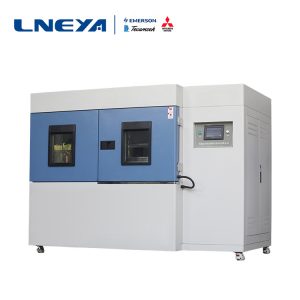

Treatment of insufficient exhaust gas in high and low temperature impact test chamber compressor

1246The efficiency of the high and low temperature impact test chamber during use is very important. If there is a shortage of high compressor exhaust, we need our LNEYA technicians to solve it in time. So, how to solve it better? The high and low tem...

세부 정보 보기 -

산업용 냉각기의 종류와 기능 및 특성에 대한 세부 정보

1036산업용 냉각기에 관해서는 누구나 알고 있어야하지만 구체적인 유형은 무엇입니까? 그것은 냉각 기능을 지속적으로 수행 할 수있는 일종의 냉각 장비이며, 이는 또한 산업 기능의 중요한 표현이기도합니다 ...

세부 정보 보기 -

Use of cold processing refrigerators for mechanical parts and comparison with liquid nitrogen

1001In the machinery manufacturing industry, the quality requirements for parts are very strict. In order to better improve the performance of machinery, improve product quality and life, a new technology-cryogenic treatment has been produced. During ...

세부 정보 보기 -

Small high and low temperature impact test chamber volume selection instructions

1296When the test product (components, components, components or complete machine) is placed in a small high and low temperature impact test chamber for testing, in order to ensure that the atmosphere around the test product can meet the environmental...

세부 정보 보기

LNEYA 산업용 냉각기 제조업체 공급 업체

LNEYA 산업용 냉각기 제조업체 공급 업체