What is a Screw Chiller

- 4 Types of Refrigeration Systems Which One Fits Your Facility

- What is a VFD chiller VFD chiller vs Non VFD chiller

- What is a Gas Chiller

- What is a Scroll Chiller

- What is a Screw Chiller

- Chiller Refrigerant Charging Tools Steps and Tips

- Chiller Low Pressure Alarm 5 Common Reasons and Solutions

- Is r22 refrigerant still available for chillers

- 2025년 8월

- 2025년 7월

- 2025년 6월

- 2025년 5월

- 2025년 3월

- 2025년 2월

- 2025년 1월

- 2024년 12월

- 2024년 11월

- 2024년 10월

- 2024년 9월

- 2024년 8월

- 2024년 7월

- 2024년 6월

- 2024년 5월

- 2024년 4월

- 2024년 3월

- 2024년 2월

- 2023년 9월

- 2023년 7월

- 2023년 6월

- 2023년 5월

- 2023년 1월

공냉식 냉각기 냉각기 냉각기 설치 냉각기 Chiller Troubleshooting 저온 조립 냉동고 냉각 냉각기 냉각 난방 순환기 냉각 난방 시스템 cooling system 이중층 유리 반응기 동적 온도 제어 시스템 냉동고 가스 냉각 냉각기 난방 순환기 산업용 냉각기 산업용 냉각 산업용 냉동고 산업용 냉장고 재킷 리액터 저온 냉각기 뉴스 제약 냉각기 공정 냉각기 원자로 냉각기 원자로 냉각 원자로 냉각 가열 원자로 가열 냉각 리액터 시스템 냉장 서큘레이터 냉장 냉각기 스크류 냉각기 반도체 냉각기 반도체 테스트 냉각기 sundi tcu 온도 제어 테스트 챔버 온도 조절기 초저온 냉각기 차량 테스트 냉각기 물 냉각기 수냉식 냉각기 wtd

While you enjoy a comfortable room temperature in your office building, as equipment in your workshop runs 24/7, screw chillers are quietly working to maintain the right temperature, hidden from view. This article explains what a screw chiller is, its operating principles, and its features. We hope this will help you make a better purchasing decision.

What is a Screw Chiller?

A screw chiller is a type of industrial refrigeration equipment. It’s so called because it uses a screw-type compressor. A screw compressor compresses low-pressure refrigerant gas to high-temperature, high-pressure gas.

This gas is cooled through condensation, throttling, and evaporation. Due to their high cooling efficiency and stable operation, screw chillers are often used in applications with high heat loads, such as HVAC, pharmaceuticals, and chemicals.

How Does a Screw Chiller Work?

The screw compressor is the core component of the screw chiller’s refrigeration cycle, so let’s start by understanding the complete refrigeration process. A screw compressor has two rotors. The drive rotor has raised teeth on its surface, which allows it to rotate actively. The driven rotor has recessed teeth that mesh with the drive rotor and rotate with it.

As the rotor rotates, it draws refrigerant vapor from the suction port into the cavity between the rotor and the casing. The meshing rotors create sealed chambers that trap refrigerant vapor, sealing the gas within the compressor. As the rotors rotate, the teeth of the two rotors gradually mesh, and the sealed cavity between them gradually shrinks.

The refrigerant is continuously compressed as the chamber volume decreases. When the rotors reach the discharge port, the volume of the cavity is compressed to its minimum, and the high-pressure gas is discharged into the condenser.

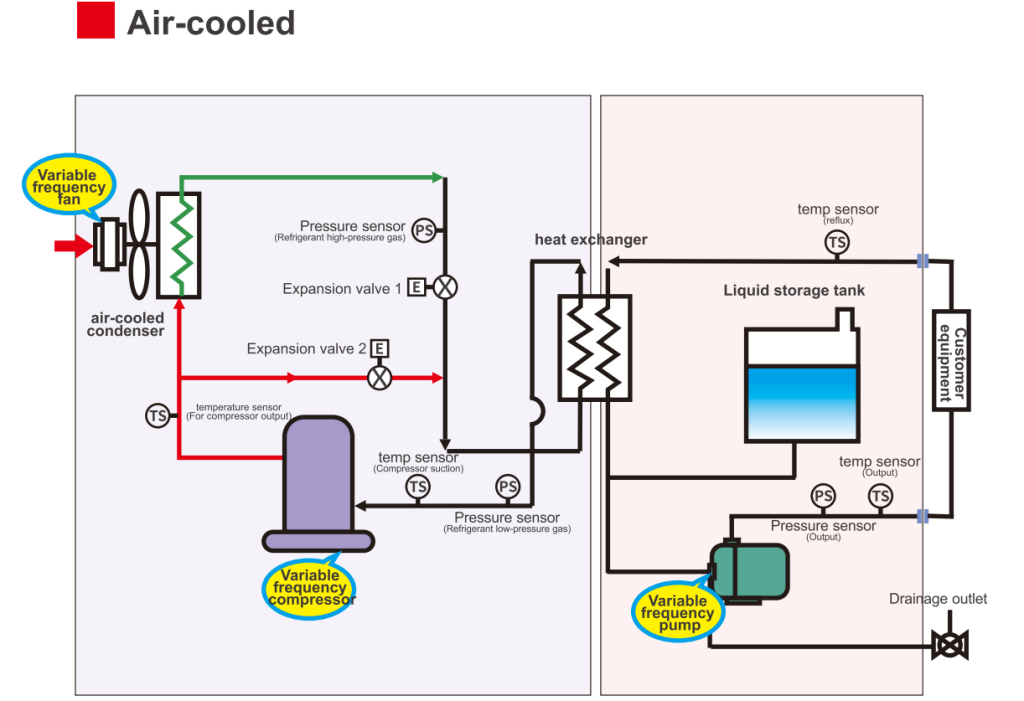

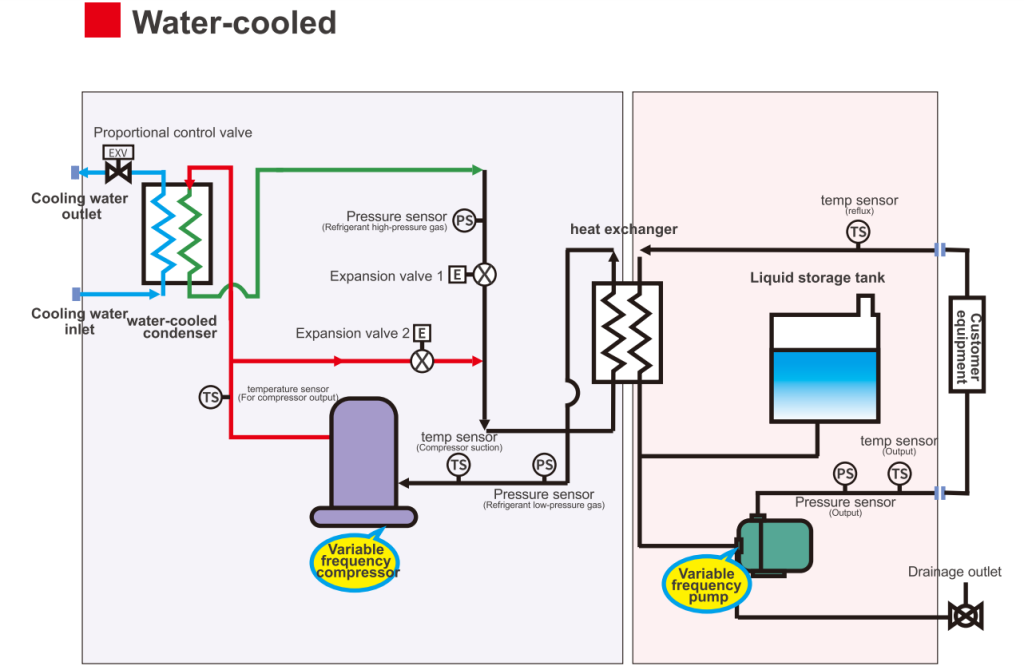

In the condenser, the heat of the refrigerant gas is removed by water (for water-cooled screw chillers) or air (for air-cooled screw chillers), condensing it into liquid. It then passes through an expansion valve with a wide inlet and a narrow outlet, reducing its pressure and temperature. Finally, it enters the evaporator, where it absorbs heat from the chilled water or air and evaporates. The evaporated refrigerant gas is drawn into the screw compressor and recompressed, beginning the next cycle.

Related: Common Compressor Types

Key Features and Advantages of Screw Chillers

There are many types of chillers, categorized by condensation method, application scenario, and function. Common equipment used for 20L reactor systems is primarily the following:

1. High Cooling Capacity

Screw compressors operate continuously between the suction, compression, and discharge stages. Their large capacity allows them to draw in and compress more refrigerant gas with each rotation, thus providing greater 냉각 용량. This is one of the key reasons why screw chillers are often used in processes with high heat loads.

2. Flexible Energy Adjustment

The cooling capacity demand of industrial chillers varies during operation. Running the equipment at full capacity during low loads wastes electricity and accelerates equipment wear. However, screw chillers can flexibly adjust their cooling capacity based on load.

Two common adjustment methods are slide valve adjustment and variable frequency drive adjustment. A slide valve inside a screw compressor, like a faucet, controls the amount of refrigerant gas drawn in.

Most slide valves can be adjusted continuously between 25% and 100% of cooling capacity. Variable frequency drive using a variable frequency drive (VFD) to adjust the motor speed.

3. High Operational Stability

Compared to piston compressors, screw compressors have fewer internal moving parts and virtually no impact from the reciprocating pistons. This results in less mechanical wear, vibration, and noise. Even under high-intensity, high-cooling-capacity conditions and long-term operation, screw chillers are less prone to overload than smaller chillers.

4. Strong Compatibility

Because screw chillers can adjust their cooling capacity, they operate stably under both low and high load conditions. Furthermore, modern screw chillers are compatible with a variety of refrigerants, may require minor adjustments or compatibility verification when switching refrigerants.

Explore high-efficiency and energy-saving chiller solutions!

Applications of Screw Chillers

1. Industrial Production

In chemical, plastic injection molding, pharmaceutical, and semiconductor fabs, production equipment requires high temperature stability. Screw chillers can continuously provide tens to thousands of kilowatts of cooling capacity, helping to dissipate heat from equipment in a timely manner.

2. Commercial Buildings

In large shopping malls, office buildings, hotels, and other locations, chillers provide cooling for HVAC systems. Screw chillers, through variable frequency control, can flexibly adjust cooling capacity based on changes in room load, saving electricity while ensuring indoor comfort.

3. Data Centers

Data center servers generate large and frequently fluctuating heat. Screw chillers, combined with cooling towers or air cooling systems, can quickly respond to load changes, maintain stable room temperatures, and reduce server failure rates.

4. Medical and 실험실 애플리케이션

Hospital operating rooms and clean areas of laboratories have stringent temperature and humidity requirements. Screw chillers offer high stability and low noise levels, and can be used in conjunction with air handling units (AHUs) for precise temperature control.

5. Central Air Conditioning Systems

Screw chillers are essential equipment in large central air conditioning systems. They can be combined with scroll chillers and centrifugal chillers to meet the temperature control needs of multiple zones and loads.

결론

Screw chillers are commonly used in industrial applications with high heat loads and the need for long-term stable temperature control. Looking for a suitable cooling system? LNEYA offers a variety of screw equipment types and performance levels, along with one-stop customization services, to help you easily meet the temperature challenges of your industry.

Related Chillers

문의하기

TEL:전화

이메일: 이메일

위챗 및 왓츠앱:

Wechat QR

문의 사항이 있으시거나 견적이 필요하신가요? 아래 양식을 작성해 주시면 저희 팀이 24시간 이내에 답변해 드리겠습니다.

LNEYA 산업용 냉각기 제조업체 공급 업체

LNEYA 산업용 냉각기 제조업체 공급 업체